9 Machined Features

Machined Features

- BEVEL

- BOSS

- CHAMFER

- COUNTERBORE

- COUNTERSINK

- DOVETAIL

- FILLET

- KERF

- KEYWAY

- KEYSEAT

- KNURL

- LUG

- NECK

- PAD

- ROUND

- SPLINE

- SPOTFACE

- T-SLOT

The machined features in this section are common terms related to basic industry processes. These terms are often found on prints. For a better understanding of these processes, look at the models of machined features in the Print Reading Lab.

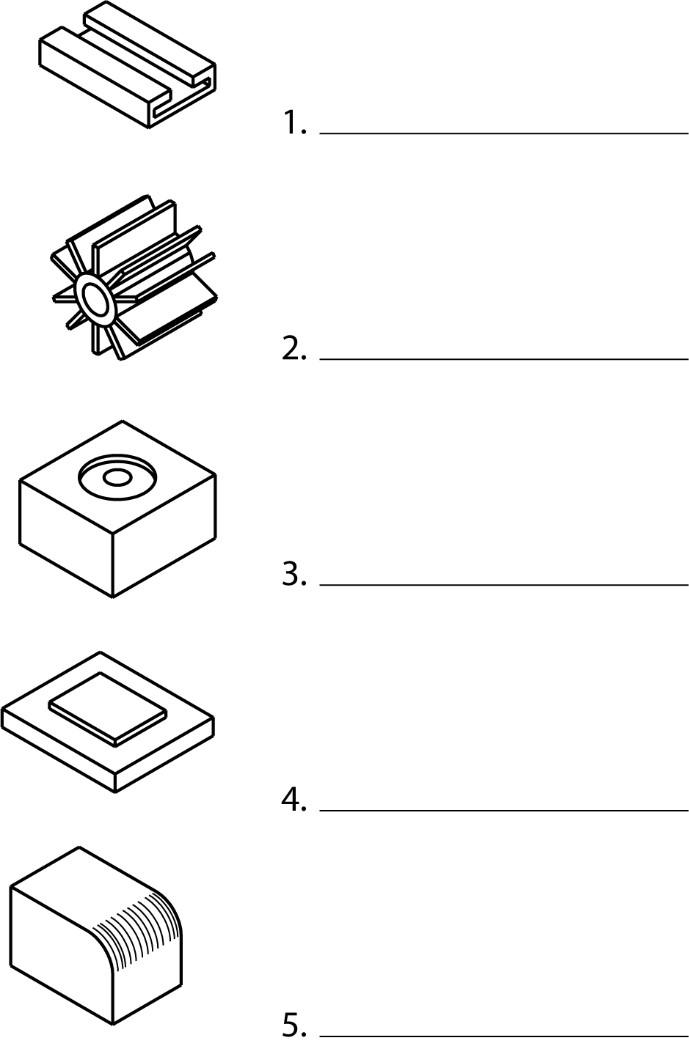

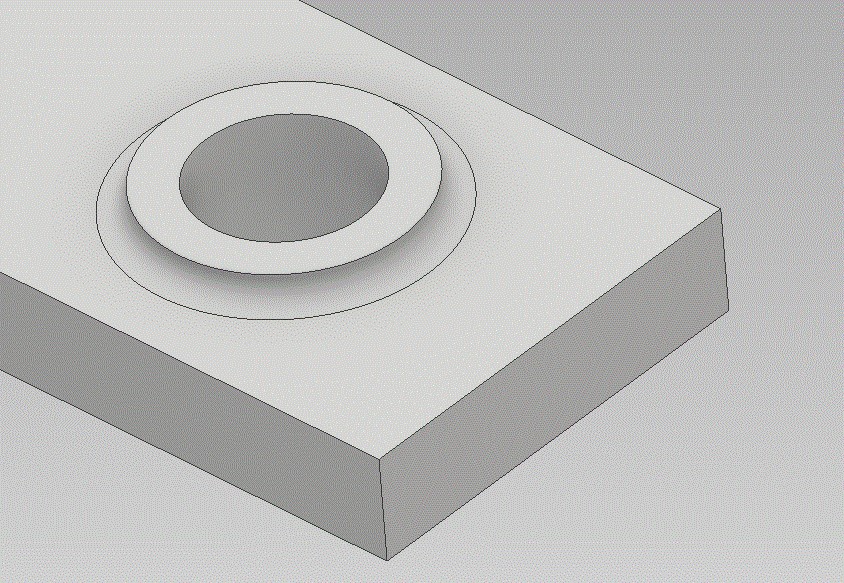

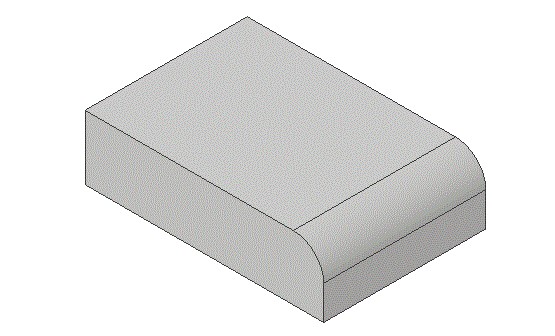

Bevel

A surface cut at an angle. In regard to welding, a bevel will normally end up being a surface prep for a weld.

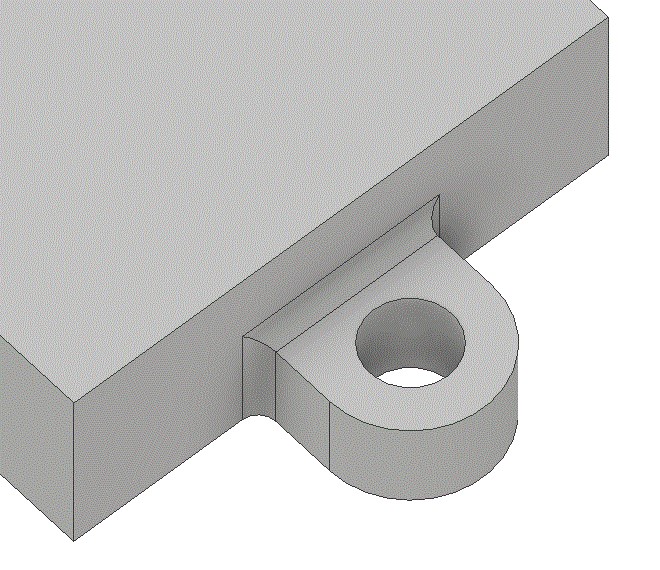

Boss

A circular pad on forgings or castings, which project out from that body of the part. The surface of the boss is machined smooth for a bold head to seat on and it has a hole drilled through to accommodate the bolt shank.

Chamfer

A process of cutting away a sharp external corner or edge. Not for welding.

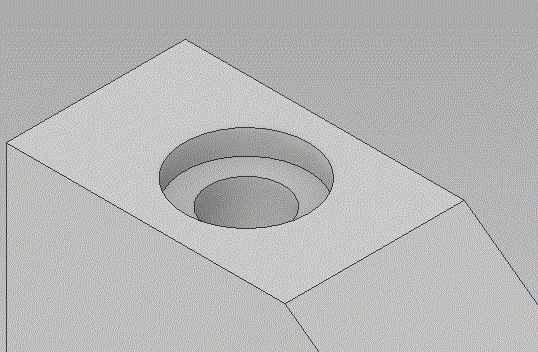

Counterbore

To enlarge drilled hole to a given diameter and depth. Usually done for recessing a bolt head.

Countersink

To machine a conical depression in a drilled hole for recessing flathead screws or bolts.

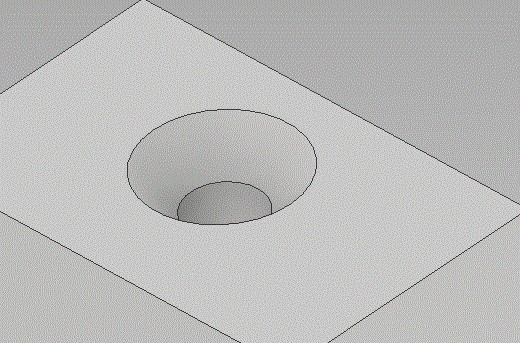

Dovetail

A slot of any depth and width, which has angled sides.

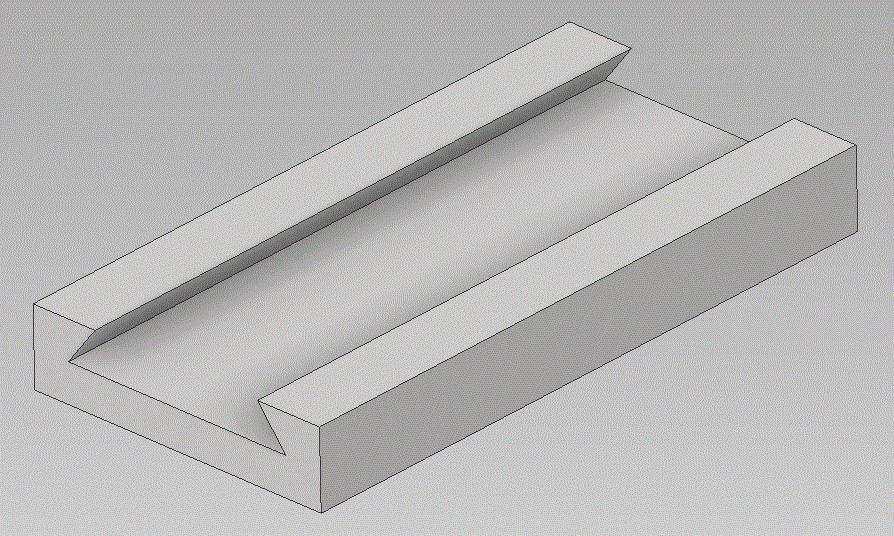

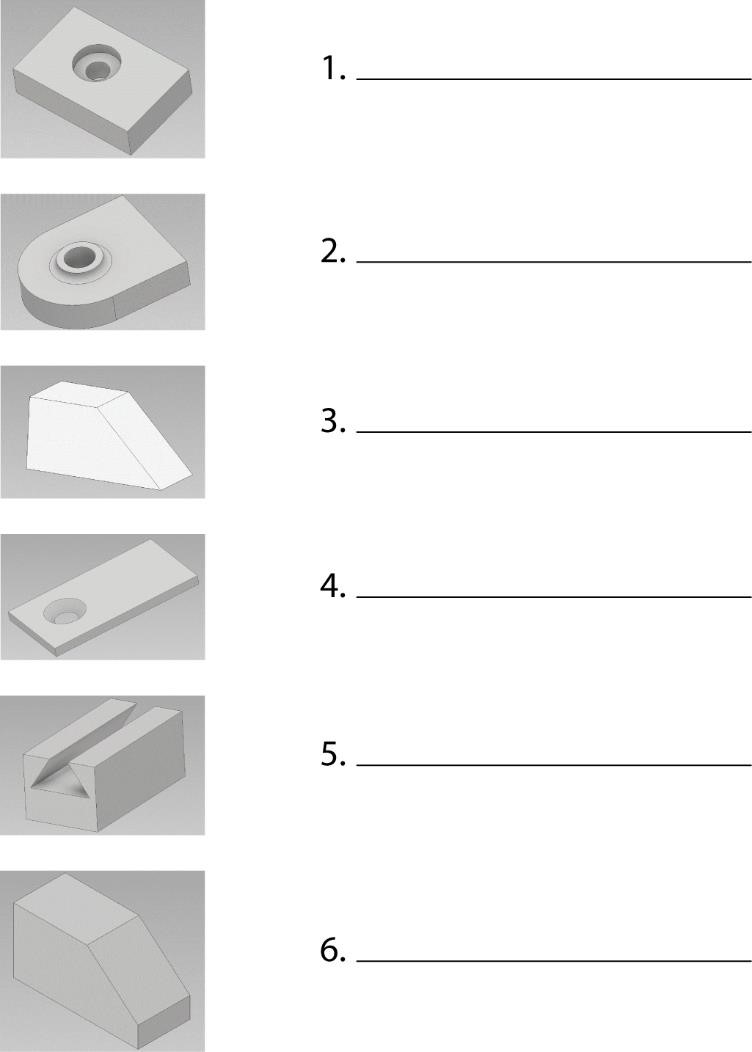

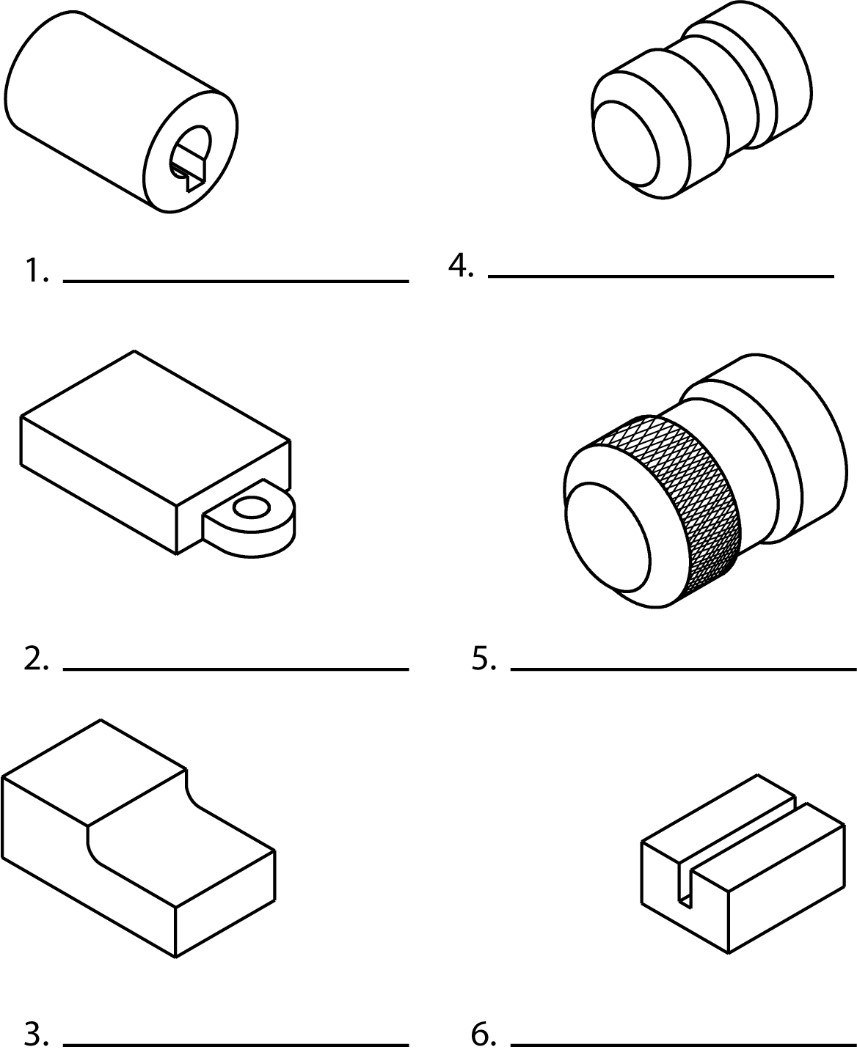

Quiz

Directions: Name the machined features shown below.

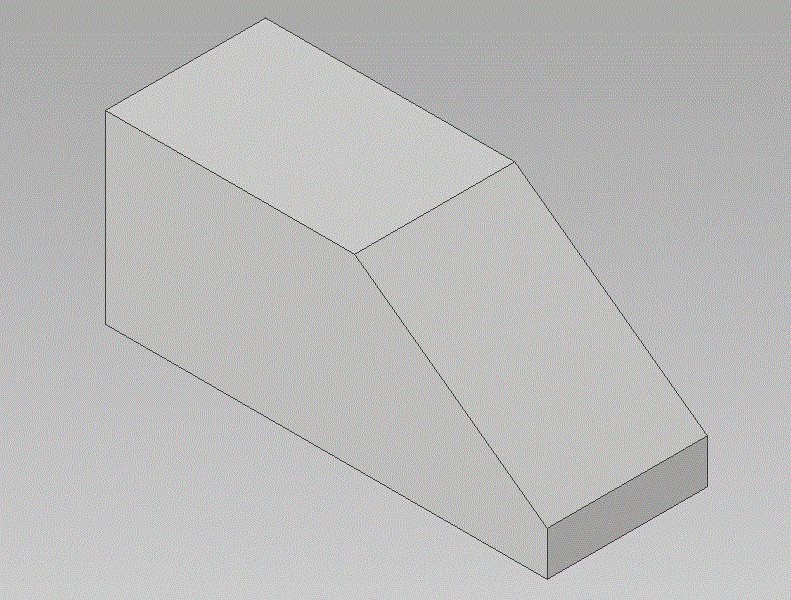

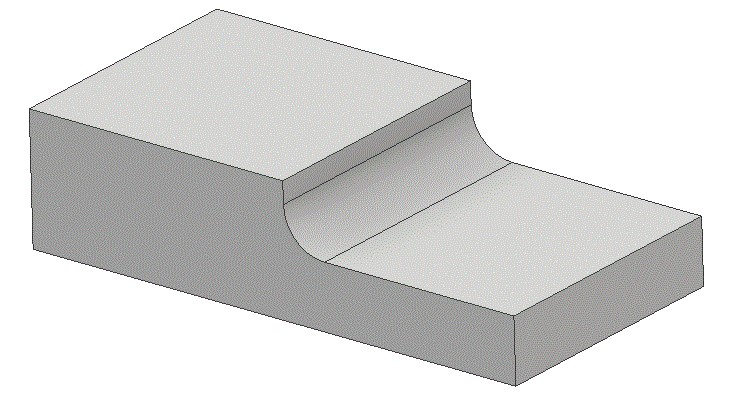

Fillet

A small radius filling formed between the inside angle of two surfaces.

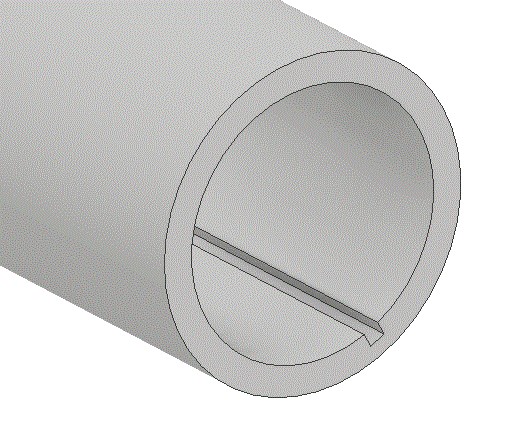

Kerf

The narrow slot formed by removing material while sawing or other machining.

Keyway

A narrow groove or slot cut in the shaft hole of a sleeve or hub for accommodating a key.

Keyseat

A narrow groove or slot cut in a shaft for accommodating a key.

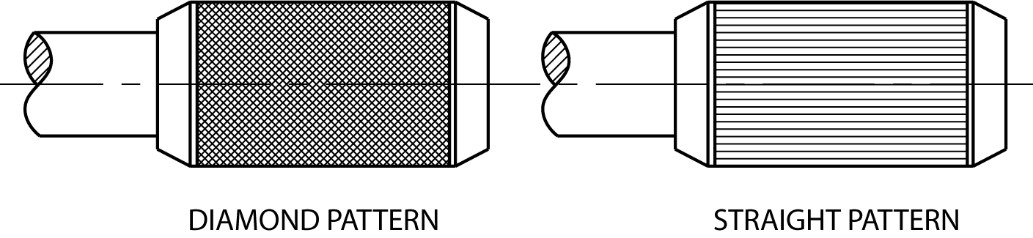

Knurl

To uniformly roughen with a diamond or straight pattern a cylindrical or flat surface.

Lug

A piece projecting out from the body of a part. Usually rectangular in cross section with a hole or slot in it.

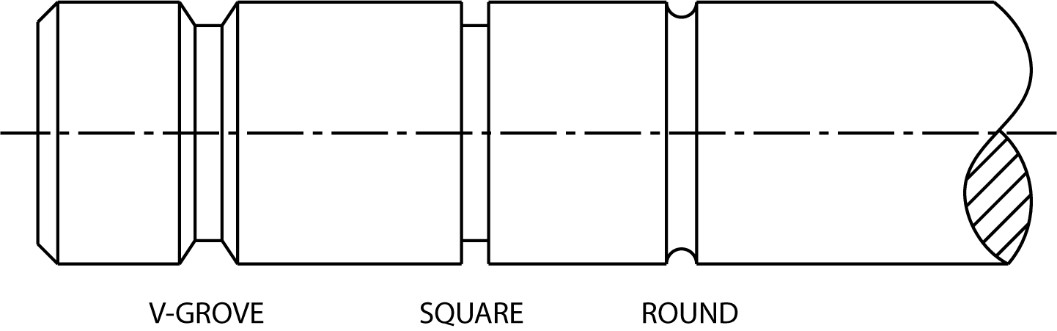

Neck

To machine a narrow groove on a cylindrical part or object.

Quiz

Directions: Name the machined features shown below. Check your answer.

Additional features and shapes.

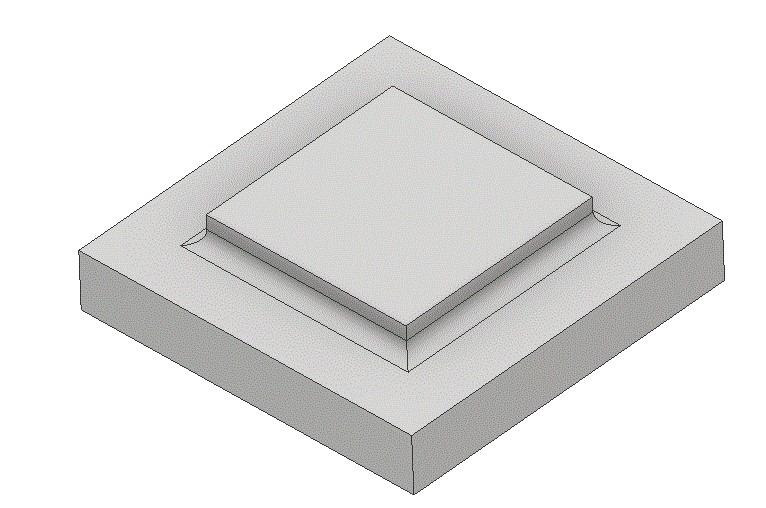

Pad

A slightly raised surface projecting out from the body of a part. The pad surface can be of any size or shape. (Remember, bosses can only be round)

Round

A small radius rounded outside corner formed between two surfaces.

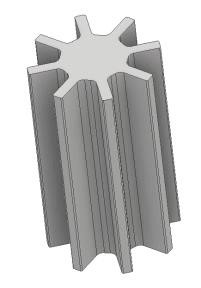

Spline

A gear-like serrated surface on a shaft. Take the place of a key when more torque strength is required.

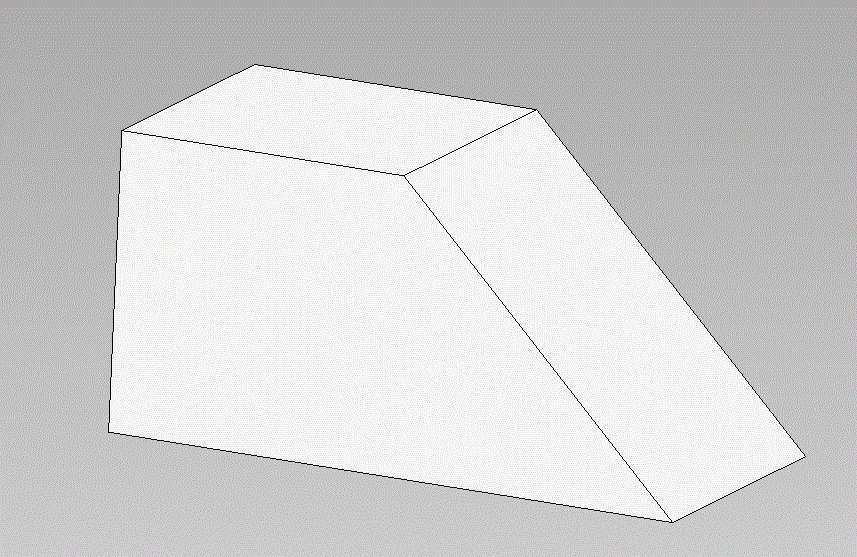

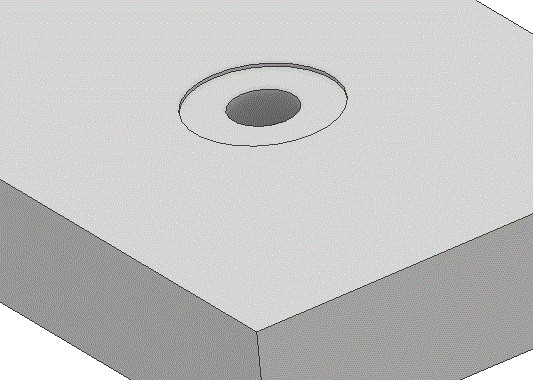

Spotface

A round surface on a casting or forging for a bold head. Usually about 1/16” deep.

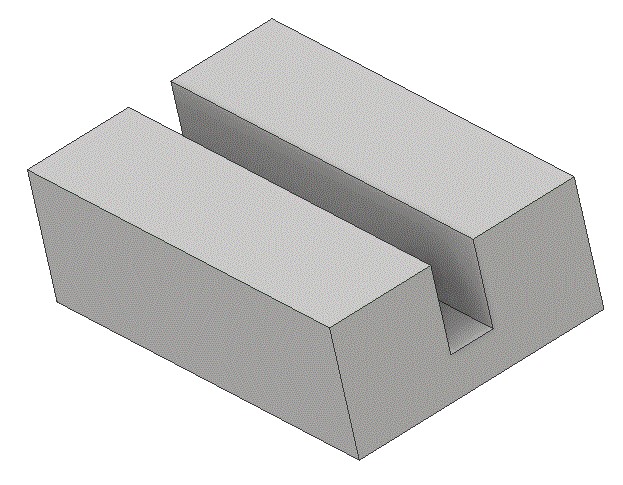

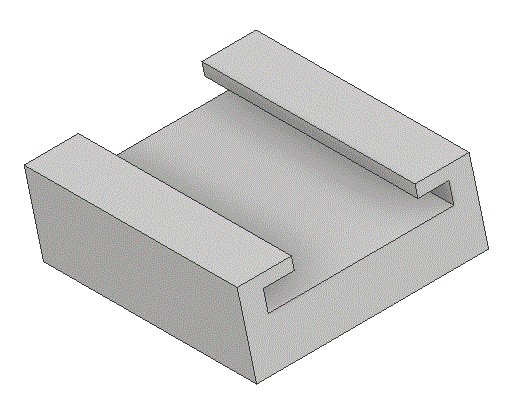

T-Slot

A slot of any dimensions to resemble a “T”.

Quiz

Directions: Name that machined features shown below. Check your Answers.