5 Line Breaking

Line breaking. What is it? How do we do it safely? These are a few of the things we will cover in this section.

At times while working in the industrial trades it will be necessary to be exposed to the contents of a tank, vessel, or piping system. There are several reasons why we may need to be exposed to these contents. A few of those reasons follow and are not limited to. Doing weld repair, valve replacement, opening a valve, replacing pipe and or pipe fittings, hot tapping of a pipeline, and removing manhole covers to name a few. Anytime you can be exposed to the contents of a pipe, vessel, or tank it should be treated as a line break. This can be a very hazardous task, but if you follow some key safety rules and procedures this work can all be done safely.

Just like any other safety rule that needs to be followed, it is going to be dependent upon: Who are you working for? Where is the work is taking place physically? In what region or state is this word occurring? There could be a wide variety of safety rules to follow, and we will cover some of the basics.

Like performing hot work and doing work in confined spaces, permits are often required. It is becoming more commonplace for companies to require the use of a line break permit. This permit should serve as a checklist to make sure that you follow a standard procedure, order of operations to assure you can safely complete this task.

Working on pipe systems can be simple or complicated. Pipe systems length could be 20’ or 300’. Pipe sizes could be 2” or 24”. All of these will have an impact on your line break. You will become more comfortable the more you do this type of work but do let getting comfortable become complacency.

This would be a difficult pipe run to trace. There are many twists and turns and the pipe is all painted the same color making it difficult to trace.

No matter the work you preparing to complete you should embrace the permit process and understand there are here to help you complete your task safely.

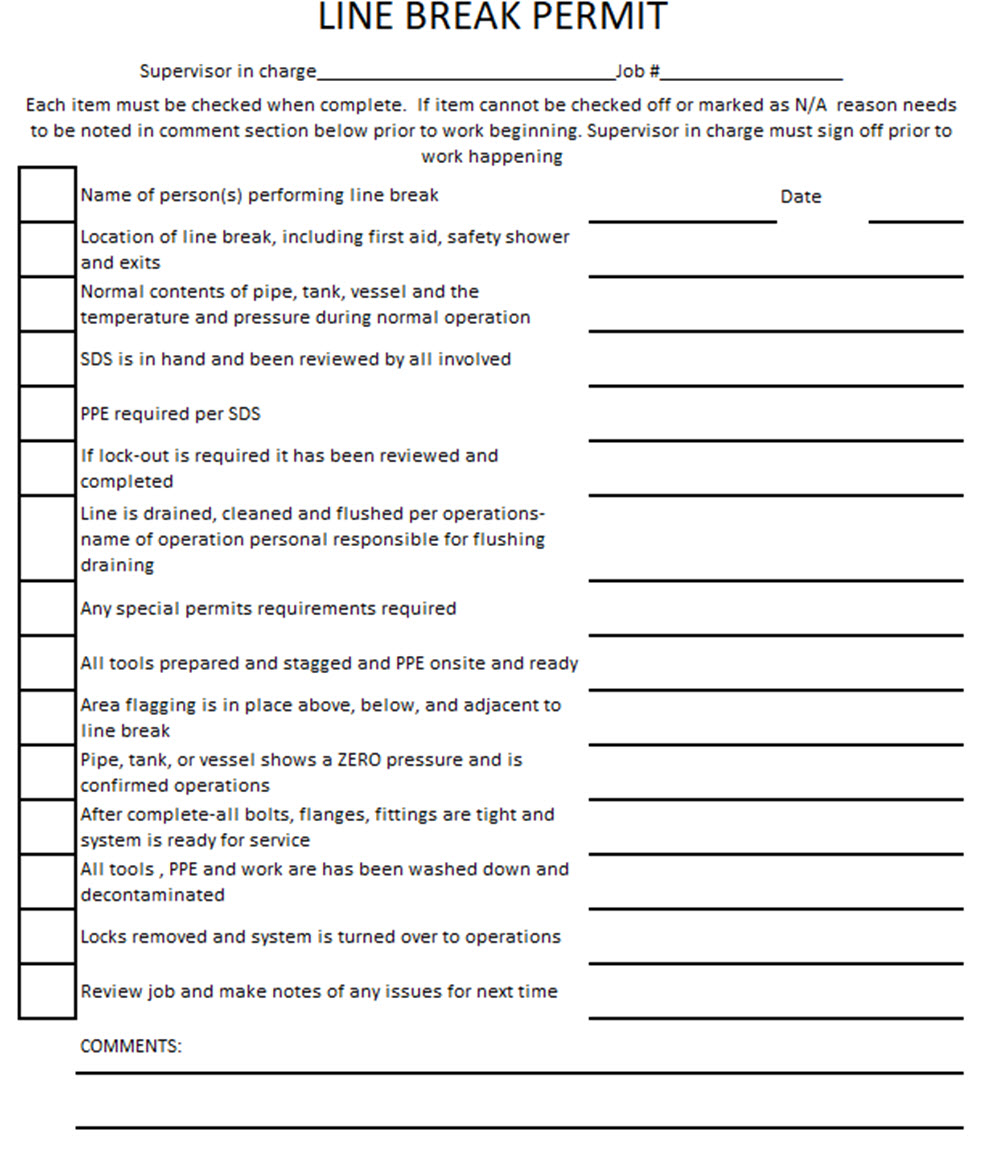

This is an example of a very simple line break permit.

Let us look at each section of the Permit to better understand what we are doing.

- Supervisor in charge– You likely will be directed by your supervisor to complete this work, and this will serve s your point of contact should an issue arise while doing a line break. They should be able to answer any question and help give guidance.

- Check off Each Item– Each section must be checked off. This will help to identify tools, PPE, and any other safety concerns that you might encounter while performing work.

- Name of Person(s)-EVERYONE involved in the work must take part in filling out this permit. Everyone needs to be on the same page. This is a good time to talk over how the work will happen and anything that has or has not worked or issues that have happened prior.

- Location- You need to know where the work is happening. This will get familiar with the layout of the area, exits, safety showers, and first aid locations.

- What is in the line-This will help you understand what the normal contents are, the temperature, and the pressure of the contents.

- SDS in hand-The SDS is broke out into 16 sections and it is a standard form so all SDS’s look similar except for maybe the font style and size. There is a lot of info here, the more you look over them the easy it will become to understand them. Sections 1, 4, 5, 6, 8 & 9 are probably the sections most referred to when line-breaking but you should look over every section of each SDS you use.

- 1) Identification-What is the chemical called, contact info the manufacturer or responsible party. What does this chemical or recommended uses?

- 2) Hazard Identification-What are the associated hazards with this chemical. Is it flammable? Are there any other not-listed hazards or special precautions?

- 3) Composition-What are the ingredients of this chemical.

- 4) First Aid-If I do get exposed to this chemical, how do I treat it with first aid?

- 5) Fire Fighting- If there happens to be a fire, how do I safely fight a fire?

- 6) Accidental Release-Recommendations for clean-up or containment of unplanned spills and releases.

- 7) Handle and Storage- How to best handle and store chemicals.

- 8) PPE-What is the best way to protect workers and what PPE level should be used.

- 9) Physical and Chemical Properties-What does it look like, smell like, what is the flashpoint and density. Freeze and melting point among other information.

- 10) Stability and Reactivity-What does this react with, how stable is this chemical, and other special considerations that should be avoided.

- 11) Toxicological Information-Routes of exposure. List of symptoms and description of short-term, long-term, and immediate exposure.

- 12) Ecological Information (non-mandatory)-Environmental impact of exposure

- 13) Disposal Considerations (non-mandatory)- Best practice for removal and disposal.

- 14) Transport Information (non-mandatory)- Best practices for shipping.

- 15) Regulatory Information (non-mandatory)- Other info not covered by the previous section of SDS.

- 16) Other Information-When was this first prepared a when was the last revision.

- PPE per SDS-Make sure you have the recommend PPE and it is in good condition. Your company may require using a higher level of PPE. Sometimes this seems like overkill but, safety is NUMBER ONE! If your company ever requires you to use a higher level of PPE, embrace that and know they care for your health.

- LOCK-OUT- If a Lock-Out is needed, be sure you fully understand what is being locked out and you follow Lock-Out procedures required.

- The line is Drained-This work is normally completed by the operations department that operates the equipment being worked on. It is always good to have a contact person to verify this work is complete and walk down the system with them and identify where the system has been draining and flushed from. This is also very important that you have contact with someone familiar with the system to help you trace down the pipe run. As shown in an earlier picture, pipe runs can be very complicated and you must be sure and comfortable that you know the exact location or origins and termination of the pipe that you are breaking into.

- Special Permits-These could be lock-out, confined space, or another special permit.

- Tools, PPE ready-Make sure all needed tools, parts, and PPE are on site and ready to use. The job will go much smoother if prepped.

- Flagging-Make sure you keep your work area controlled and safe. Many times, this work will be overhead, and you should make sure to control all foot traffic and otherwise so others in the area are not exposed to the contents of the line break. Flagging and perhaps other co-workers sue a lookout in the area to keep people away are needed.

- Zero Pressure-Make sure the pipe, tank, or vessel is a ZERO pressure. This is normally done on a prior step but is a good reminder to verify before breaking into line.

- Complete-Make sure all joints are put back to normal and everything is tight and ready for service.

- Wash down-Depending on the content of the line where you should wash down tools and PPE before leaving the area. This will help assure you do not bring any chemicals back to your tool storage area and lockers.

- Remove Locks-Be sure to remove locks so operations can put back into service.

- Review-One of the most important items. What worked well, what did not? What could you next time to get the job done safer or faster?

Here are a few terms that are commonly used when completing a line break.

Low Point Drain-The lowest point on the piping, tank, or vessel that which fluid or contents can be drained.

High Point Vent-The highest point at which air can be let into the piping, tank, or vessel to aid in draining. A long pipe run without a High Point Vent can be difficult to drain and may give a false indication of draining due to Vapor Lock.

Vapor Lock-When air cannot enter the pipe, tank, or vessel to replace the contents of the drain fluids the flow will be very slow and, in some cases, stop flowing. This many times can indicate that the pipe, tank, or vessel is drained. Special attention to length and configuration of pipe run needs to be.

PPE-Personal Protective Equipment. Anything wore as required by SDS or company that keeps you safe. There are several layers and levels of PPE depending on what you are working with.

SDS-Safety Data Sheet. Used to be called MSDS, Material Safety Data Sheets. These list many things about the chemical in question and the types of First Aid PPE required to use when exposed of there is a possibility of being exposed.

Pipe Run-The point of where the piping system originates and the path in which it takes to its endpoint.

Back Flush-Running water or another non-hazardous liquid through the pipe system to aid in draining and cleaning.

Purge-When working on a vapor line the contents might be PURGED with compressed air or a non-reactive gas to evacuate all the hazardous vapors before the line break.

There is no substitute for more training and this is only meant to give you some basic information as your enter the pipe trades.