5 3 Piece 90°

Three piece turn-

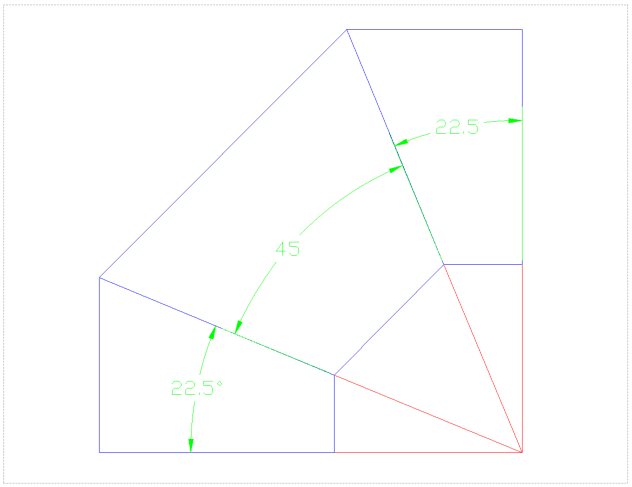

We know that when building a two piece 90° turn we needed to cut two pieces at 45°. When making a three piece turn we will need to add one more piece of pipe and thus change the angle we need to cut.

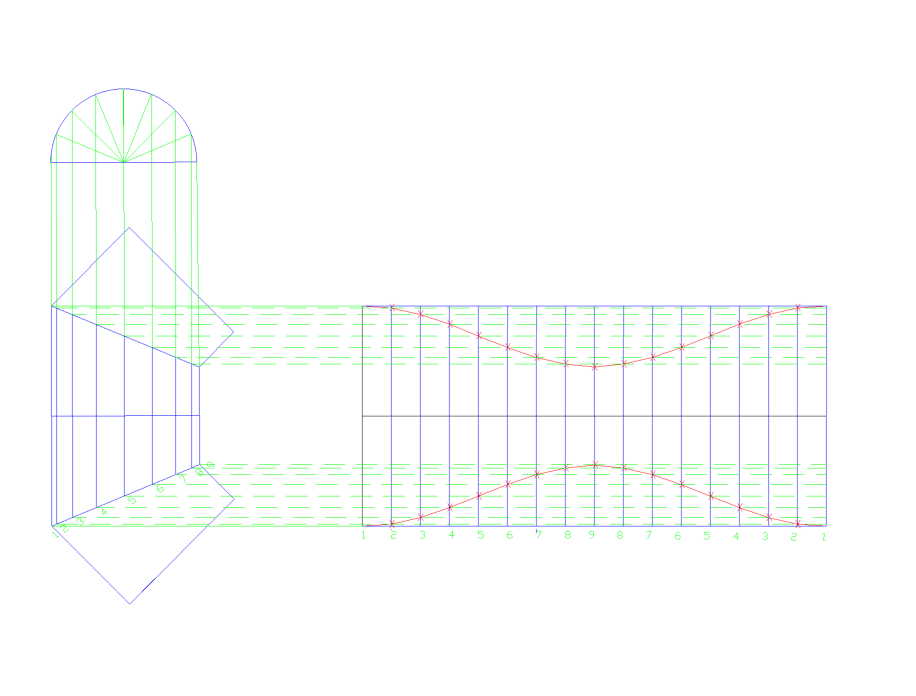

The plan view of the joint will look like this. We have bisected the joint to show what the finished angle will be, once our template is completed.

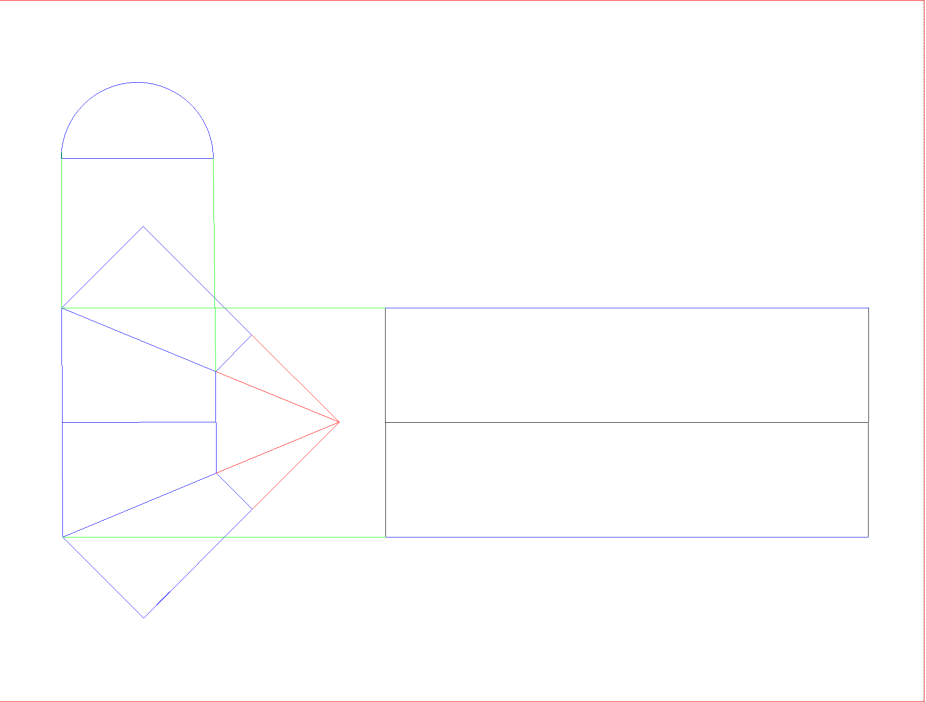

When will use the center portion of our elbow to make our stretch-out and begin to develop the template.

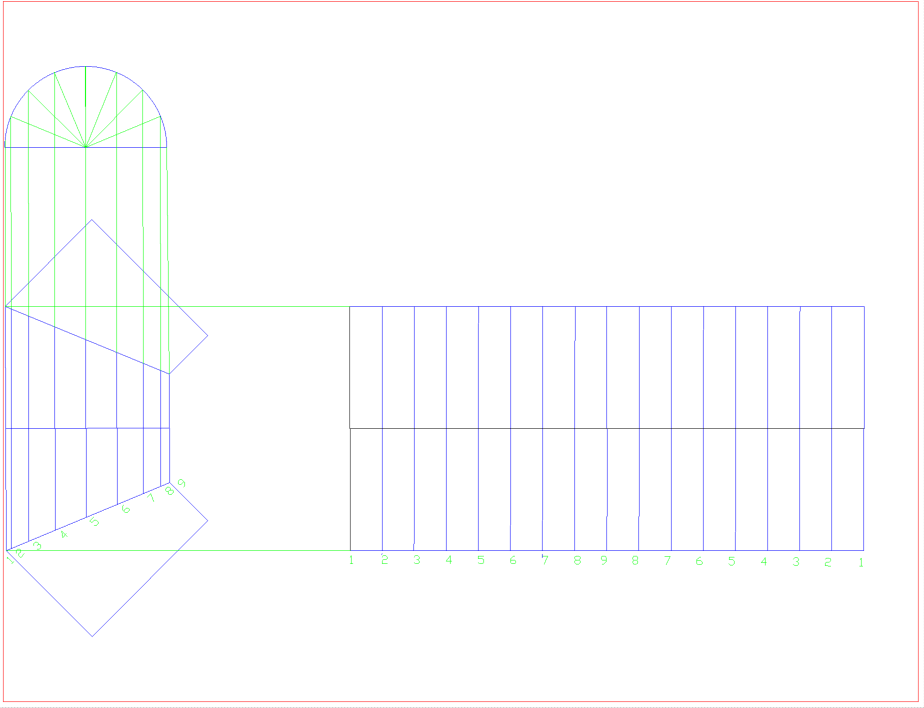

As before, we will draw a half circle off one end and also draw our stretch-out. The green lines are to show how to transfer elements from one drawing to another. You will need to calculate the stretch-out depending on what size pipe you are working with. Since we will be making a template that can be used to cut two ends at same time, the dark line on stretch out is in reference to center of stretch-out.

Next we will divide the half circle into 8 equal parts and the stretch-out into 16.

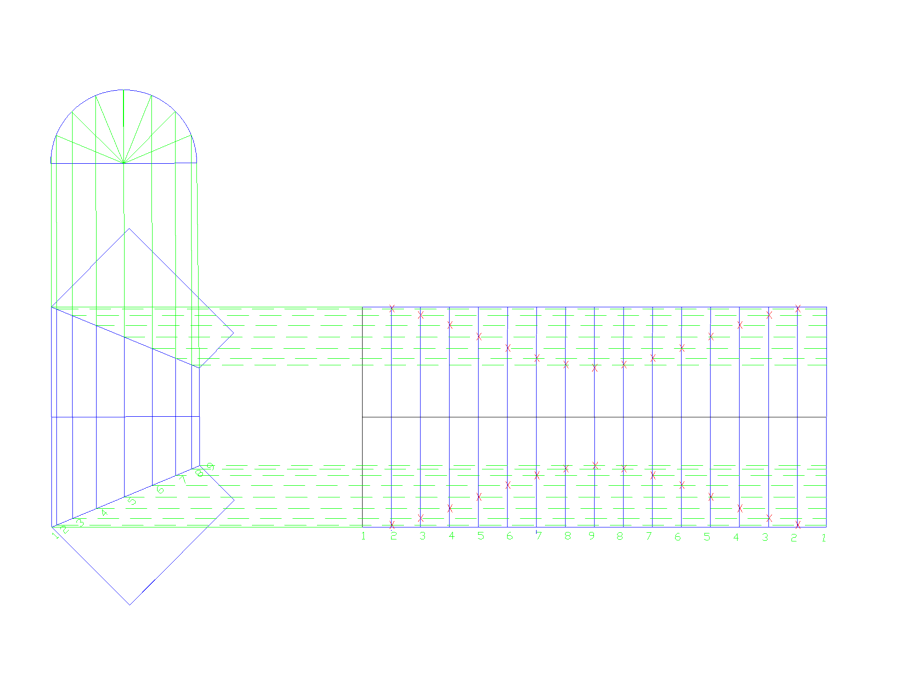

Now we can transfer elements to the stretch-out. Indicated by dashed lines you see how they reference the numbered lines on each drawing.

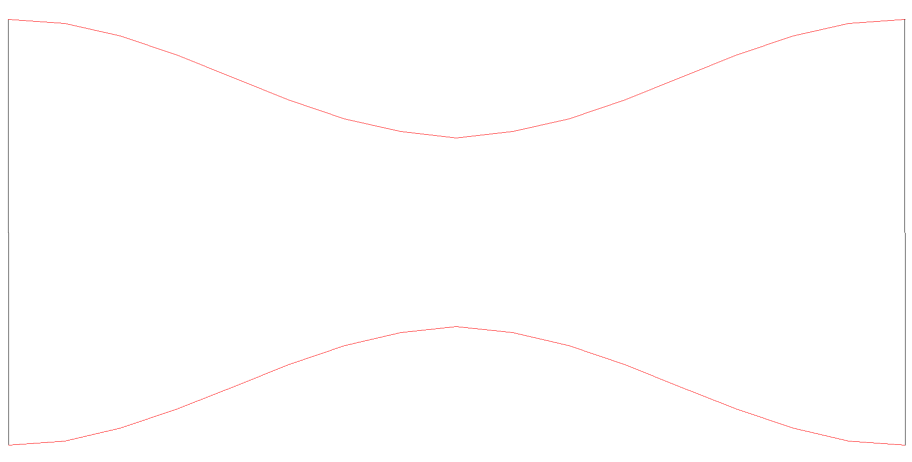

Now we can draw in our curved line to all tick marks giving the template shape.

Now remove all the non-essential lines and what is left is the final shape of the template.

You can take your template, wrap around pipe, trace the patter and then cut and fit.