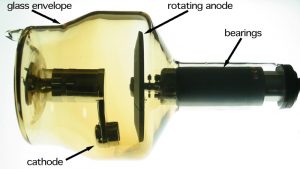

X-ray Tube and Process

X-Ray: X-ray, discovered by Wilhelm Conrad Roentgen in 1895 is widely used today both in the medical and industrial radiography fields. X-rays or x-ray photons are generated when high electrical voltage is introduced in a special vacuum tube via a hot cathode. The high-energy electrons are directed towards a metal Anode – usually a tungsten target – and when the electrons collide with the anode x-ray photons are generated and aimed in a specific direction and pattern, typically in an x-ray cabinet or vault.

The resulting x-ray photons are a non-particulate, ionizing radiation with the ability to penetrate matter. X-rays of the same energy level will be absorbed more readily by dense material as compared to less dense material. This is the reason lead, tungsten and concrete are used for shielding radiation. But since the x-rays (and gamma rays) are invisible, have no smell, and no taste, how do we know if we’re being exposed to ionizing radiation? Look ahead to units 8 & 9 to learn about all of the radiation monitoring devices used to keep people safe and maintain ALARA.

When operating an industrial x-ray system typically the Level I or Level II radiographer will follow a procedure called a “technique” for taking an x-ray of a particular casting, forging, weldment or other part. X-ray tube adjustments and settings will include Kilo-voltage (kV), milliamperage (mA), and time, usually measured in seconds or minutes. There are many other settings such as source to film distance (SFD), fixturing of the part at specified angles and part orientation, image quality indicators (IQI) and much more. As the kV and mA increase, so does the amount and intensity of the X-ray photons.