3 Joint types and Terminology

Terminology of joints may play a large role in communication with supervisors and others working on the same weldment. Understanding the concepts associated with joint design as well as identification of parts is critical for any metal worker.

Joint Types

There are 5 basic joint types used in the metal fabrication field:

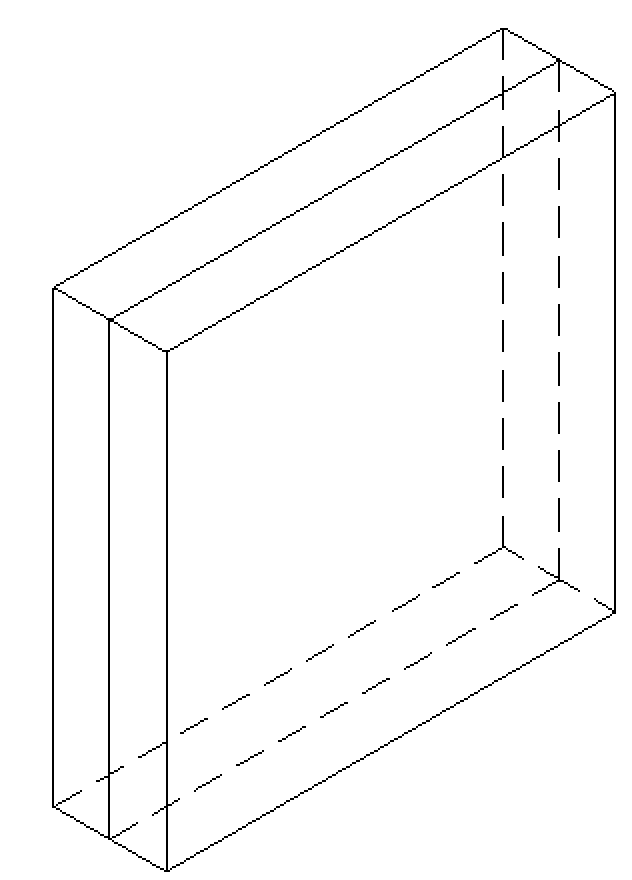

Butt Joint: A joint type in which the butting ends of one or more work pieces are aligned in approximately the same plane. A butt joint has a possibility of many prepared faces. We will talk about these in subsequent chapters. Represented is a square groove butt joint.

Possible Welds for a Butt Joint:

Square Groove

Bevel Groove

V Groove

J Groove

U Groove

Flare Bevel Groove

Flare Vee Groove

Flanged Edge

Scarf (Brazed Joint)

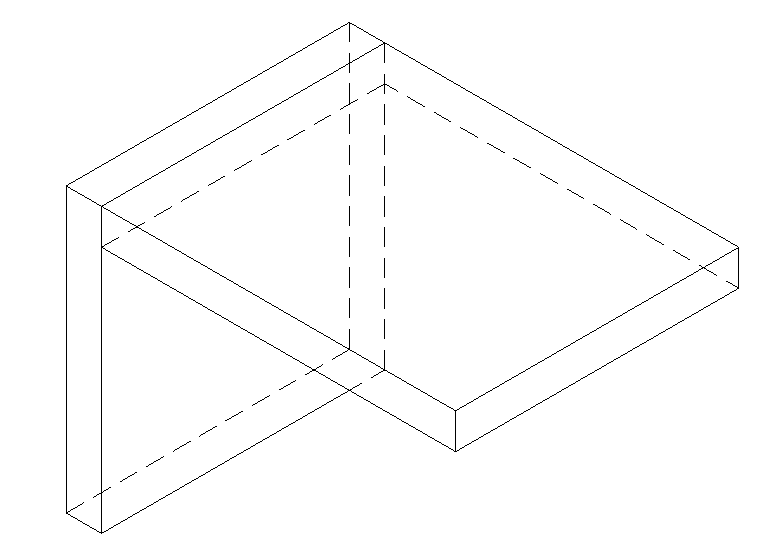

Corner Joint: being one of the most popular welds in the sheet metal industry the corner joint is used on the outer edge of the piece. This weld is a type of joint that comes together at right angles between two metal parts to form an L. These are common in the construction of boxes, box frames and similar fabrications. There are variations of a corner joint, shown is a closed corner joint.

Possible welds for a corner joint:

Fillet

Edge Flange

Corner Flange

Bevel Groove

V Groove Flare Bevel

Flare V Groove

J Groove

U Groove

Square Groove

Seam

Spot

Projection

Slot

Plug

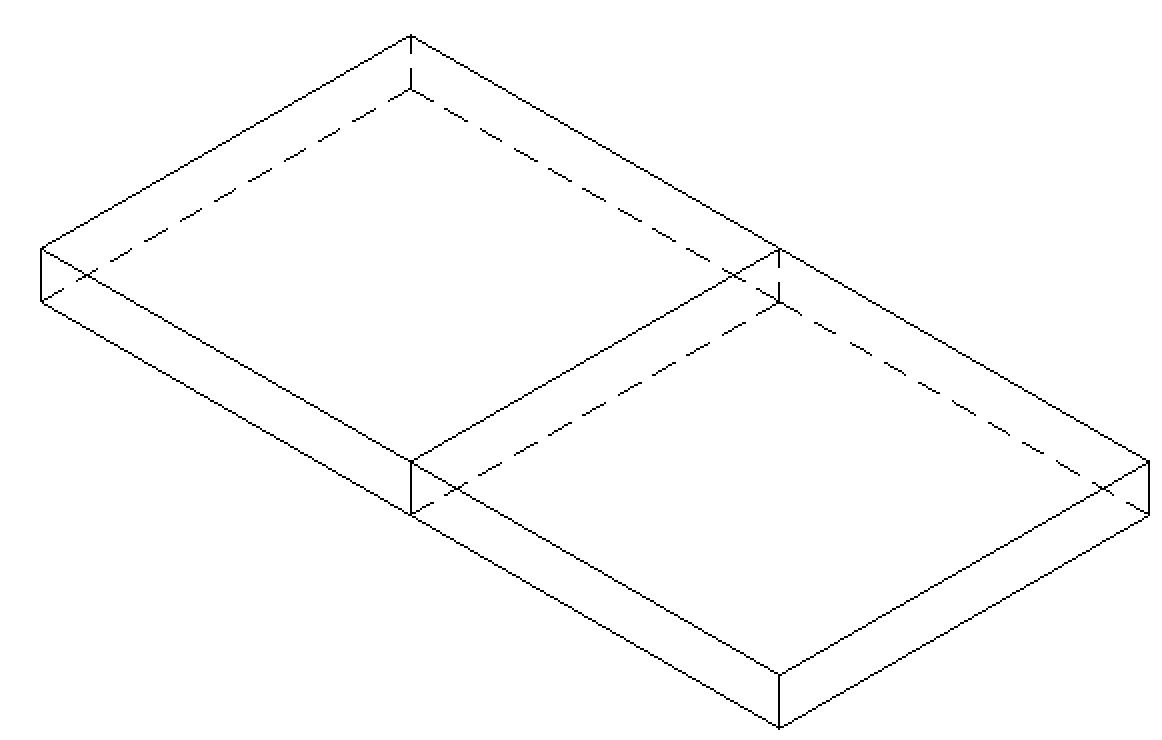

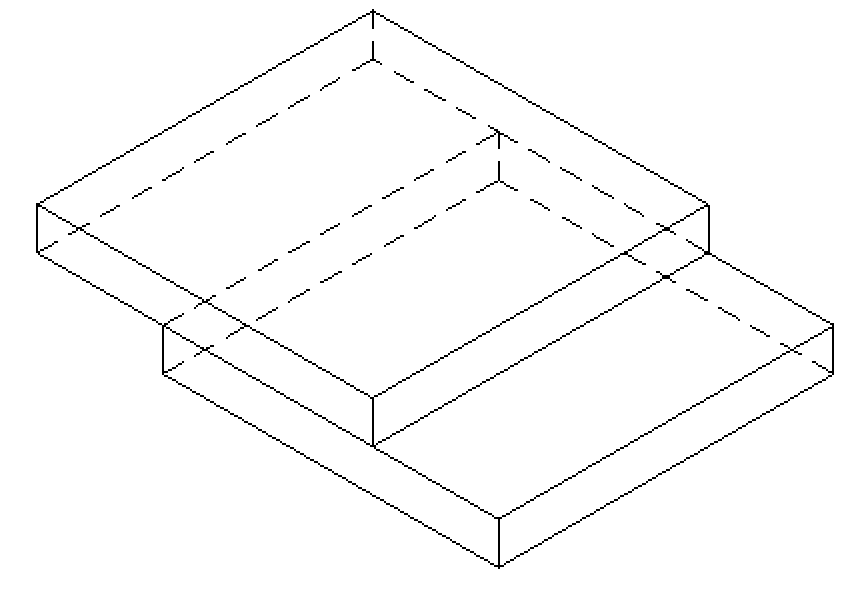

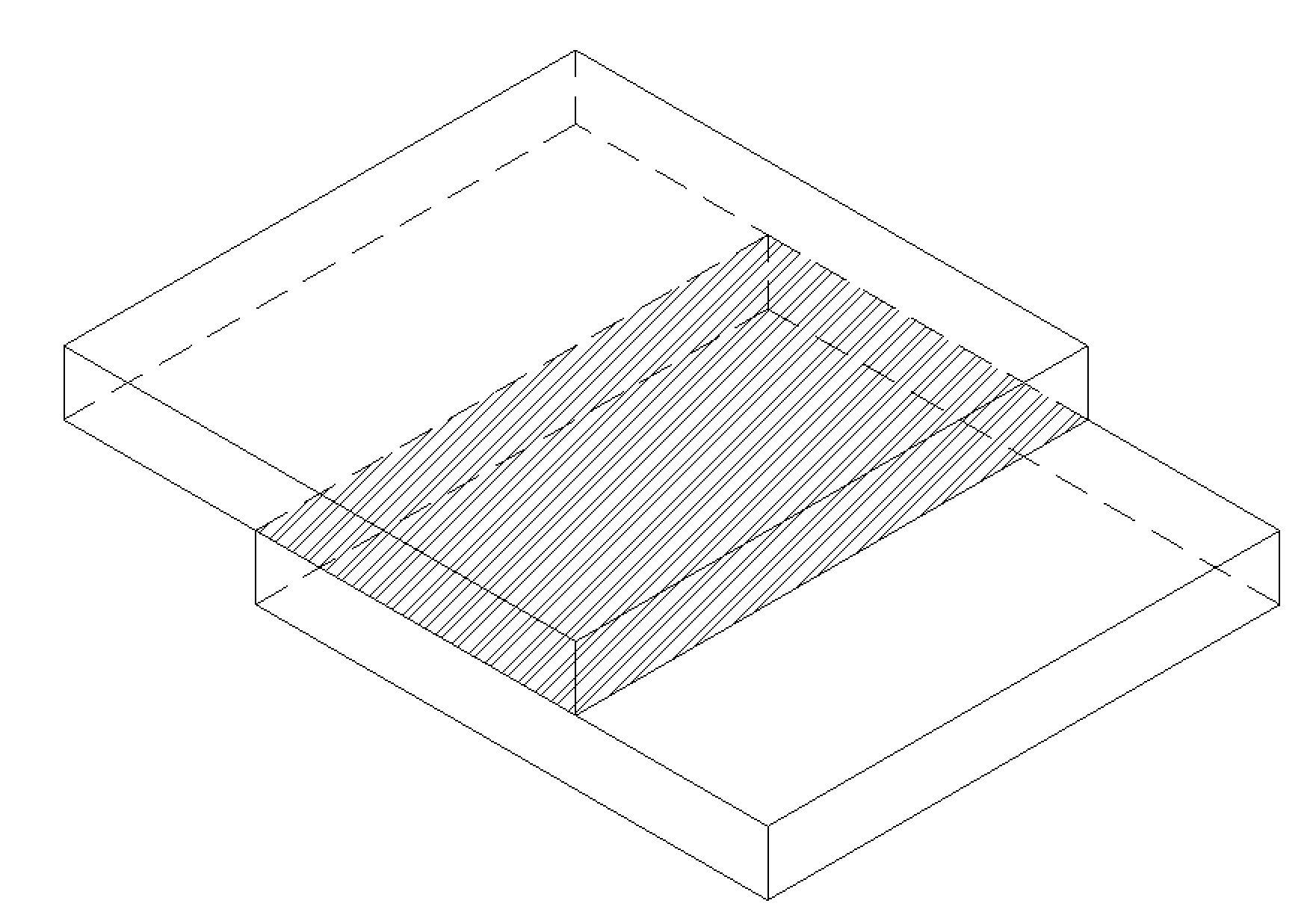

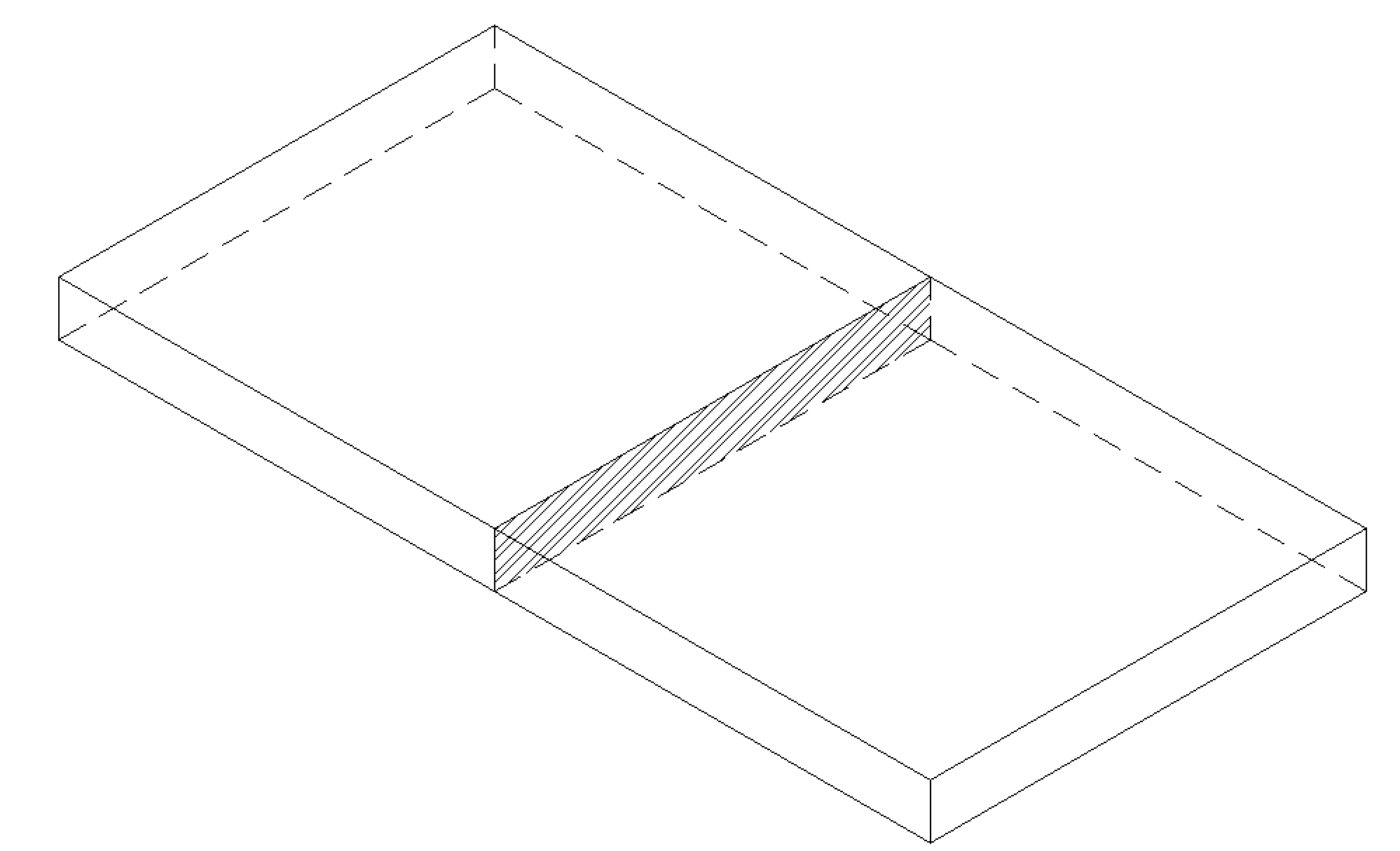

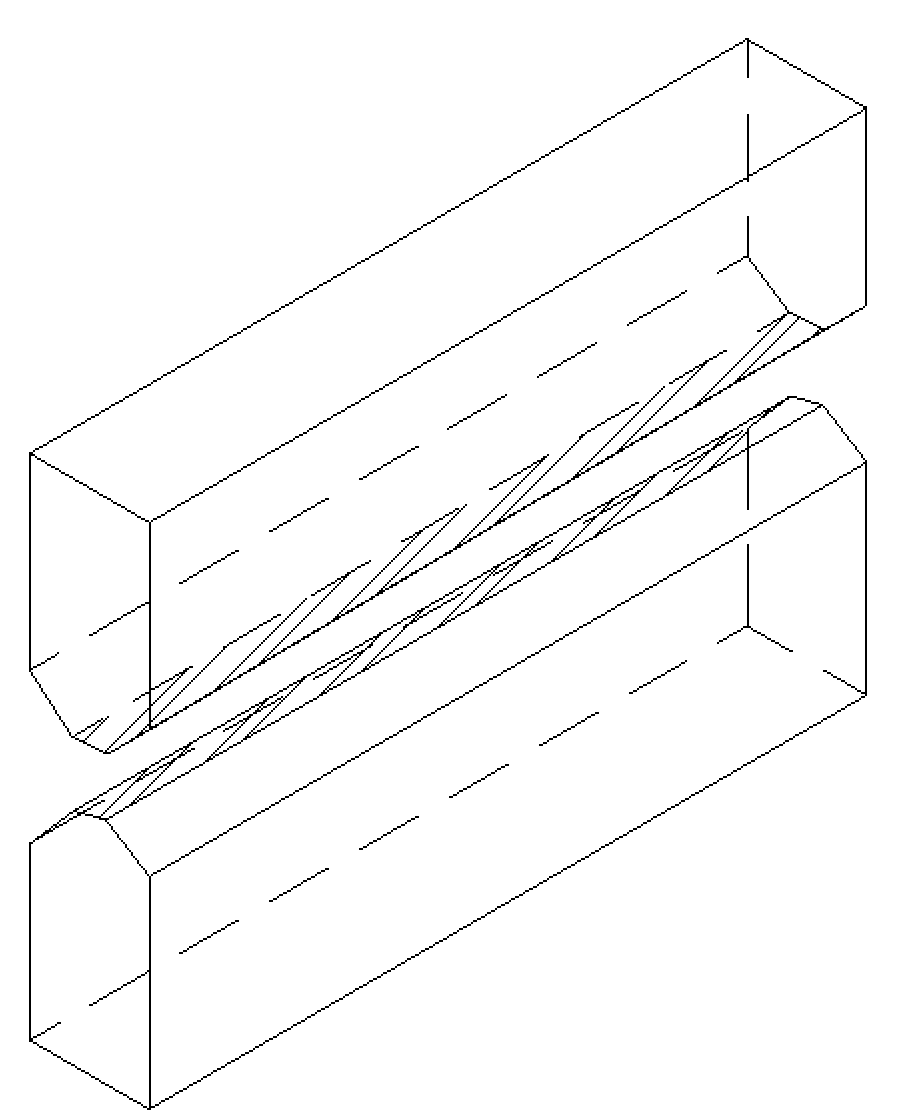

Lap Joint: A joint between two overlapping members in parallel planes.

Possible welds for lap joint:

Fillet

Bevel Groove

Square Groove

Flare V groove

J Groove

Plug

Slot

Spot

Projection

Seam

*Braze

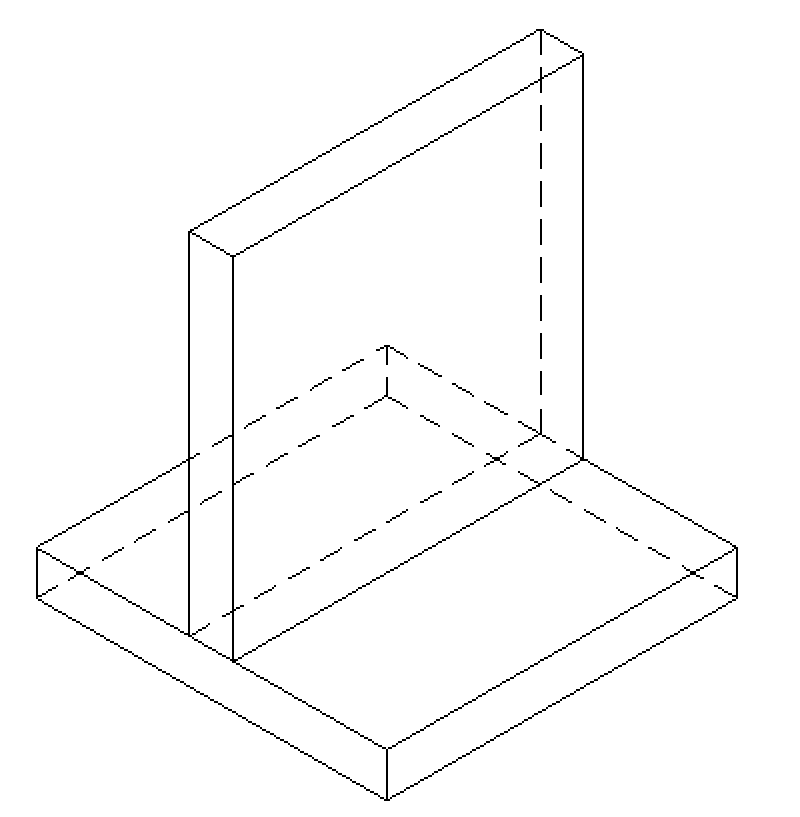

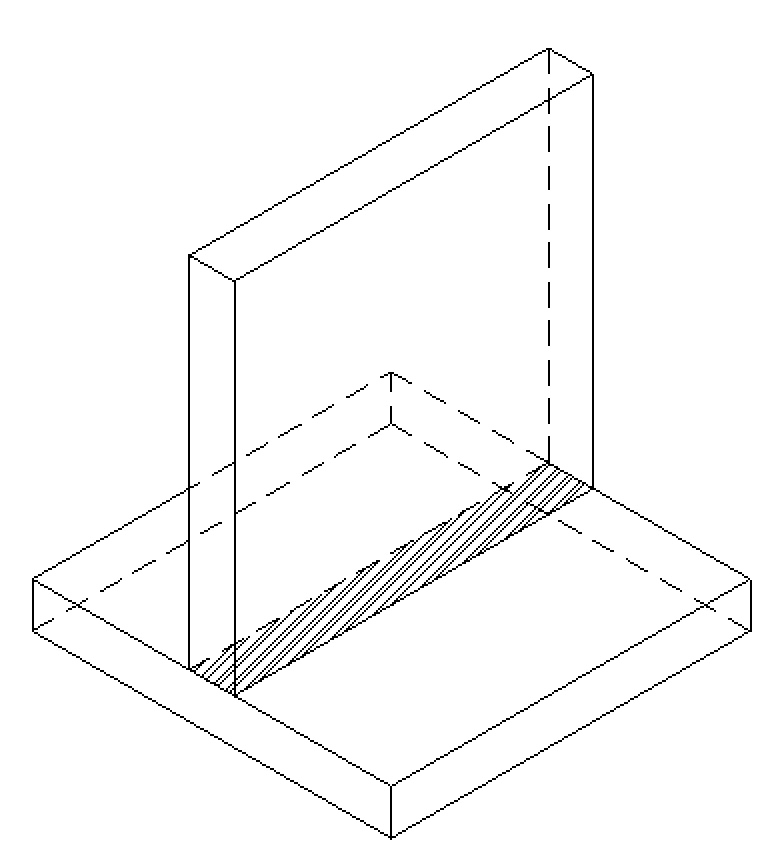

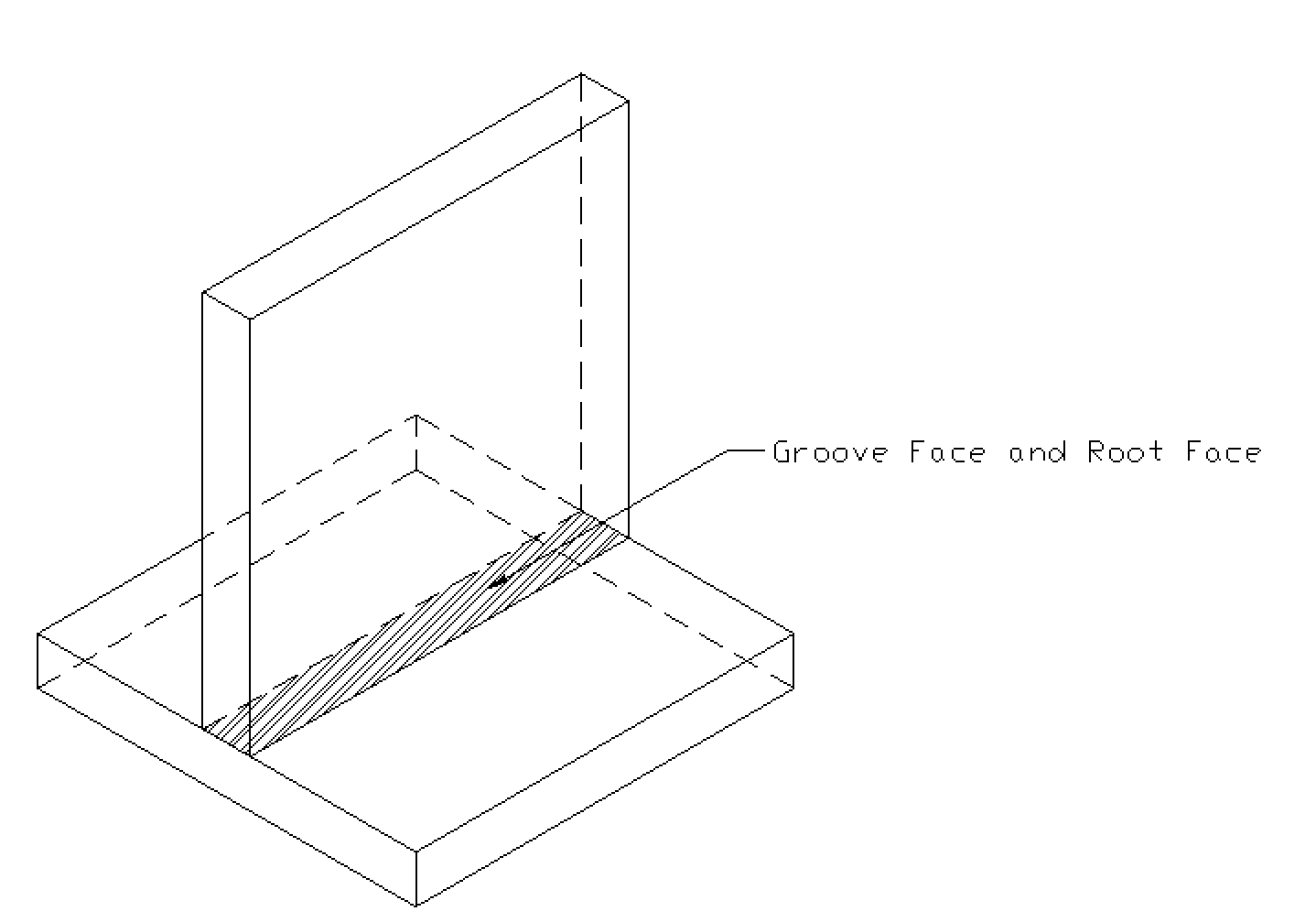

Tee Joint: A joint which are two pieces of metal are perpendicular to each other. This is one of the most common joint that will be encountered in the metal fabrication industry.

Possible welds for a Tee joint:

Fillet

Bevel Groove

Square Groove

Flare V groove

J Groove

Plug

Slot

Spot

Projection

Seam

Edge Joint: A joint formed by uniting two edges or two surfaces (as by welding) especially making a corner.

Possible welds for edge joints:

Square Groove

Bevel Groove

V Groove

Edge

J Groove

U Groove

Flare Bevel Groove

Flare V Groove

Corner Flange

Edge Flange

Seam

Joints may be left as cut but some may have a prepared surface that is determined by the engineer, designer or welder. This is commonly seen with a Butt weld when the members to be joined are larger in thickness. This will be visited in subsequent chapters.

Joint terminology

Outside of specific joint types there are some terms that will play a role in deciding the correct procedure for welding or prepping the member(s) of a weldment.

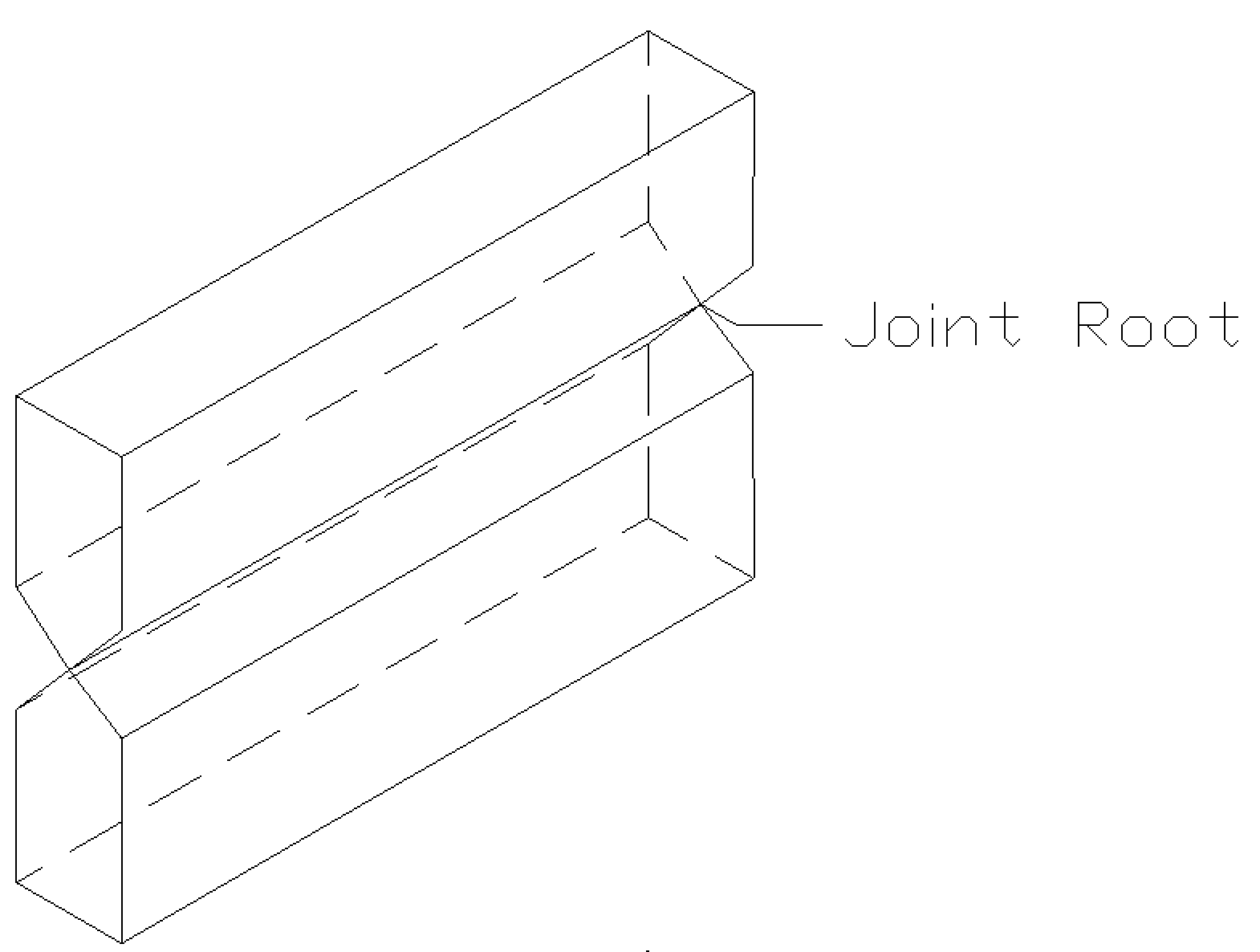

Joint Root- This is the area which is in closest proximity to another member making the joint. This could be viewed as a line, area, or a point depending on the view in front of you.

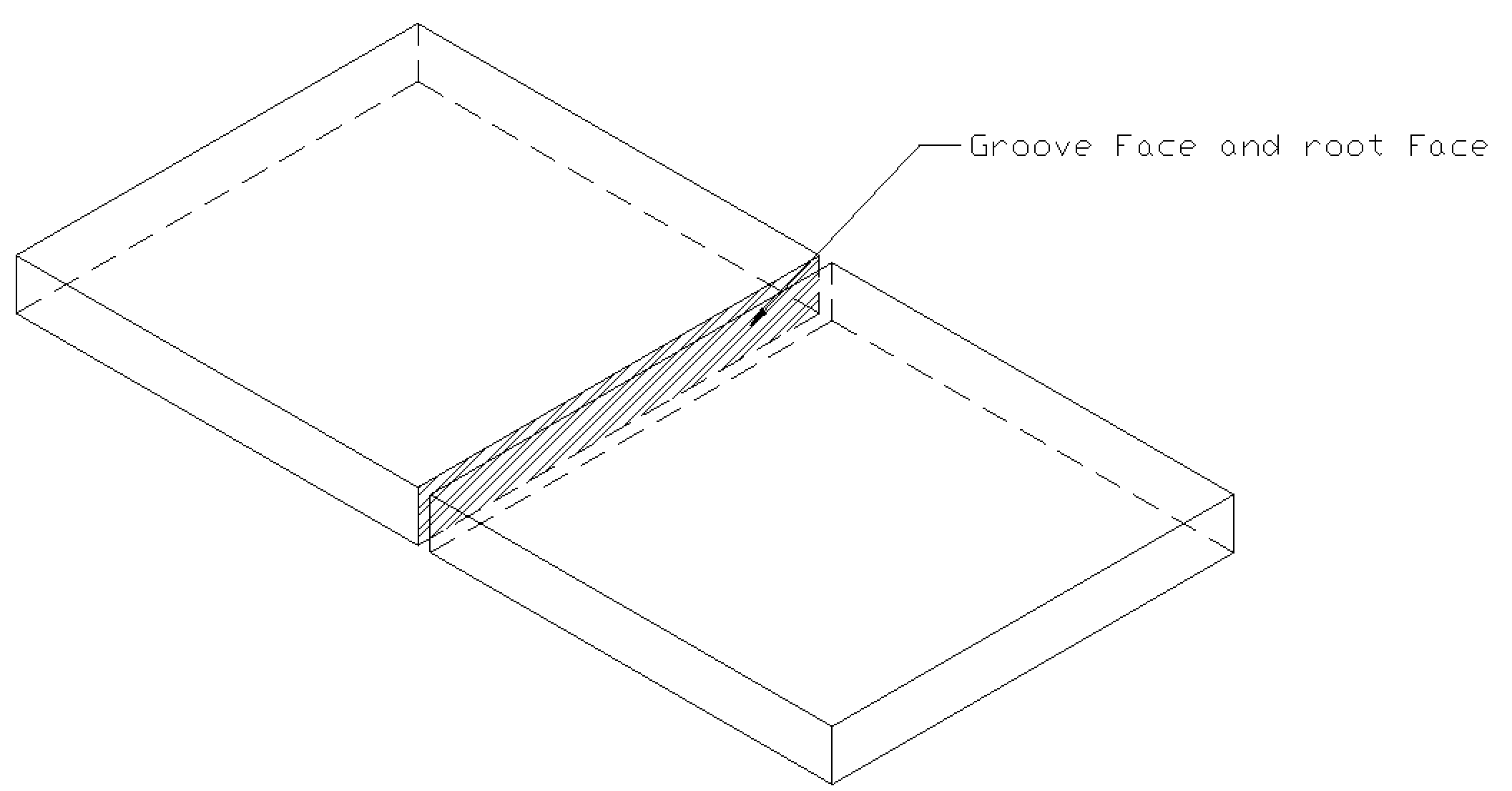

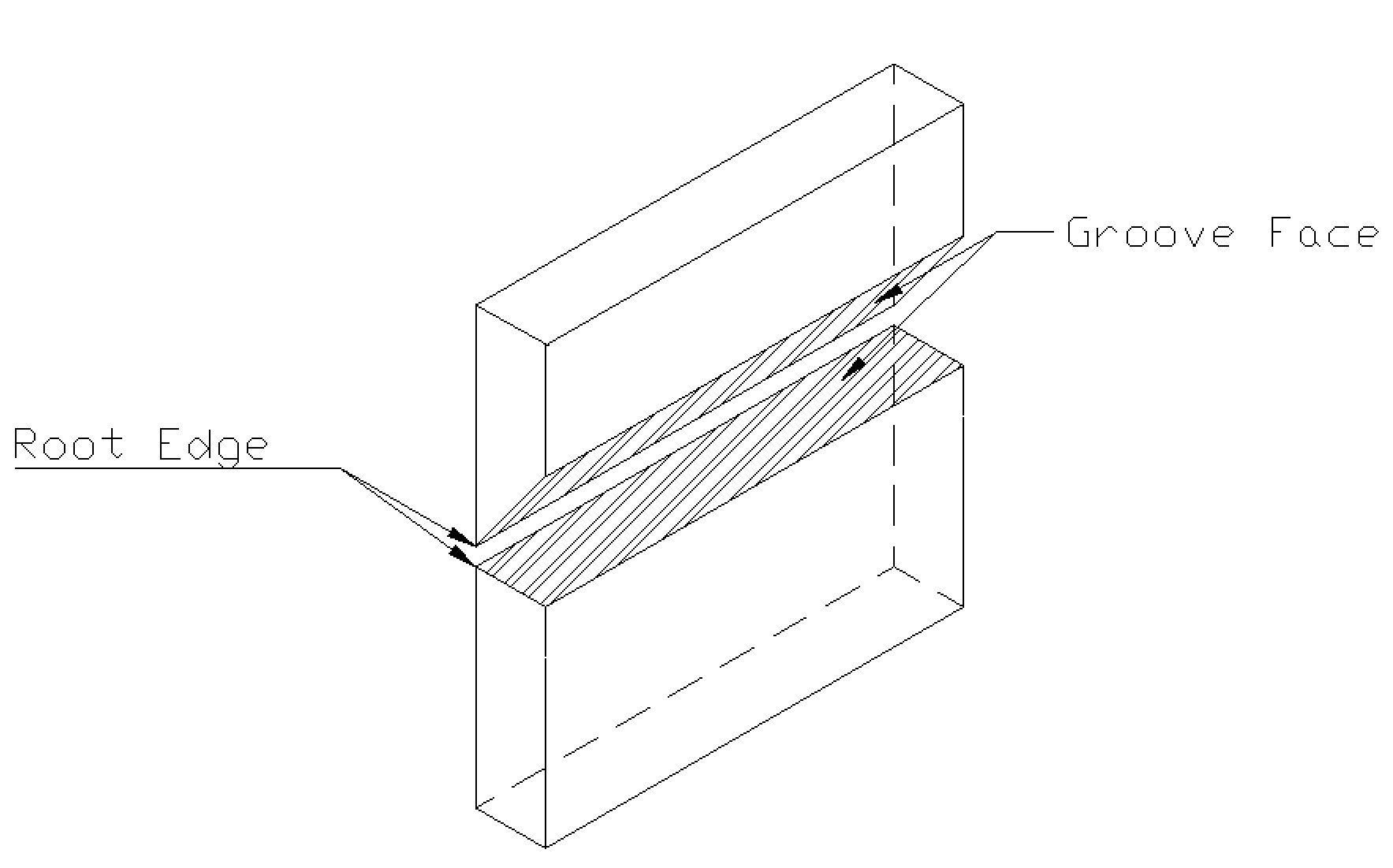

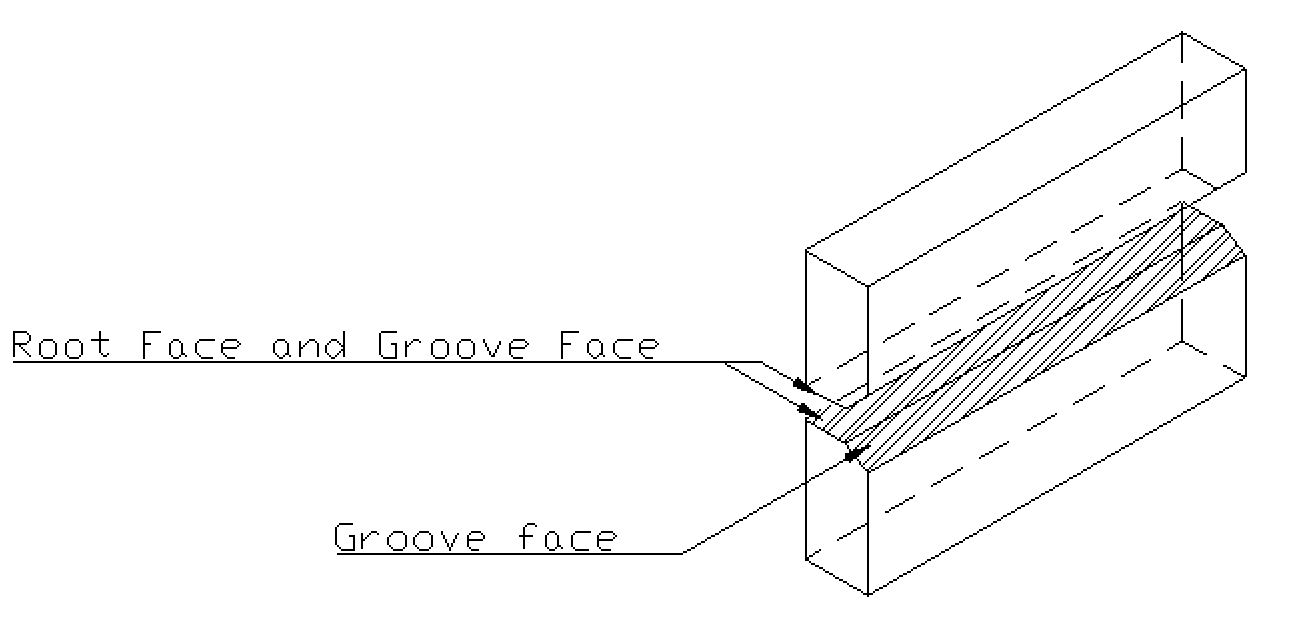

Groove Face- The surface within the groove the weld may be applied to. This can be measured at an angle from the surface of the part to the root edge.

Root Edge- This is a root face that has no width (land) to it. In GTAW it is commonly referred to as a knife edge preparation.

Root Face- This part of the prepped member is the portion of the groove face that is also within the joint root. This is commonly called a flat or land in the industry. This is usually a predetermined size even though the size is not always called out. If you take the overall thickness of the member and subtract the groove depth you will be left with the root face depth.

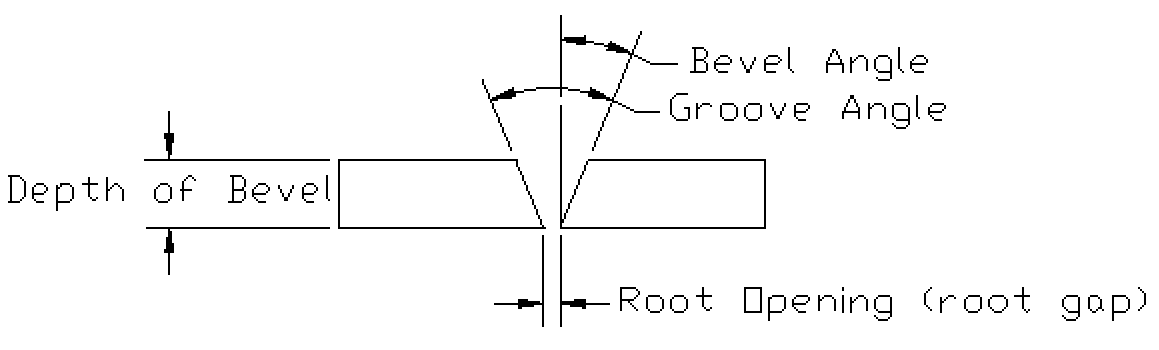

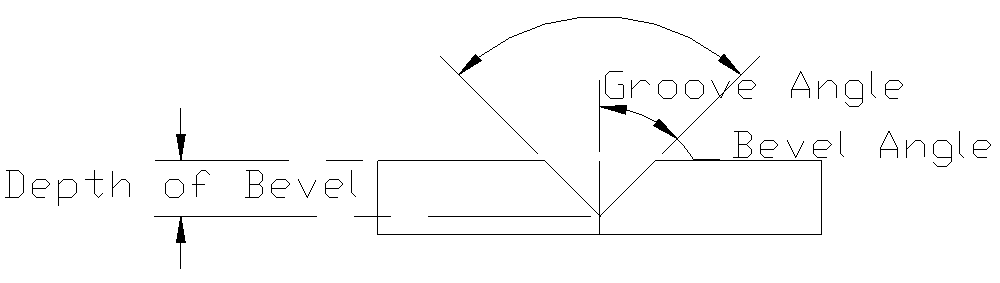

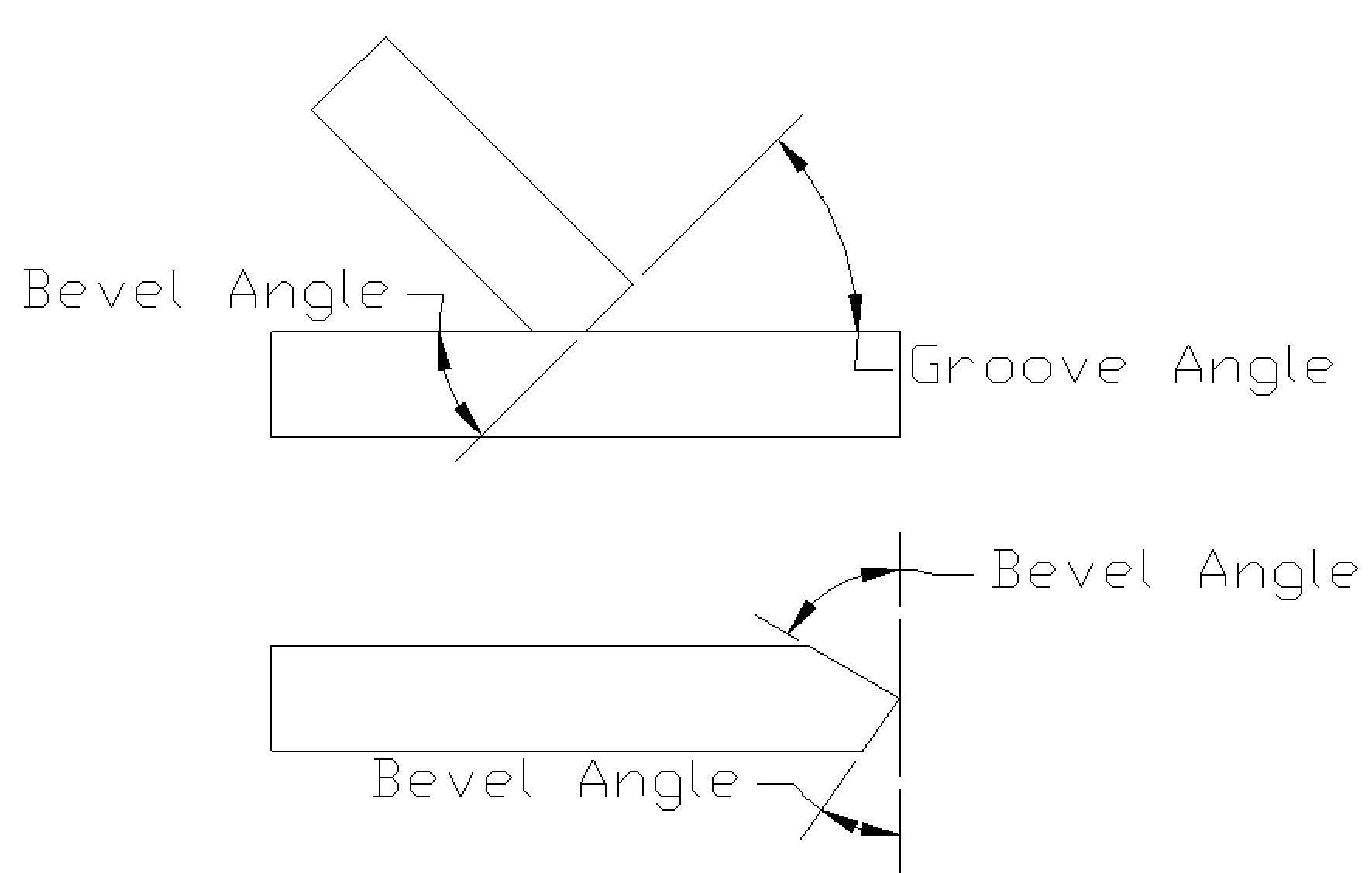

Bevel Angle- an angle between the bevel of a member and a perpendicular plane in relation to the surface. This may be only equal to half of a groove angle if the opposite joining member is also prepped. If only a single member is prepped this is also considered the groove angle.

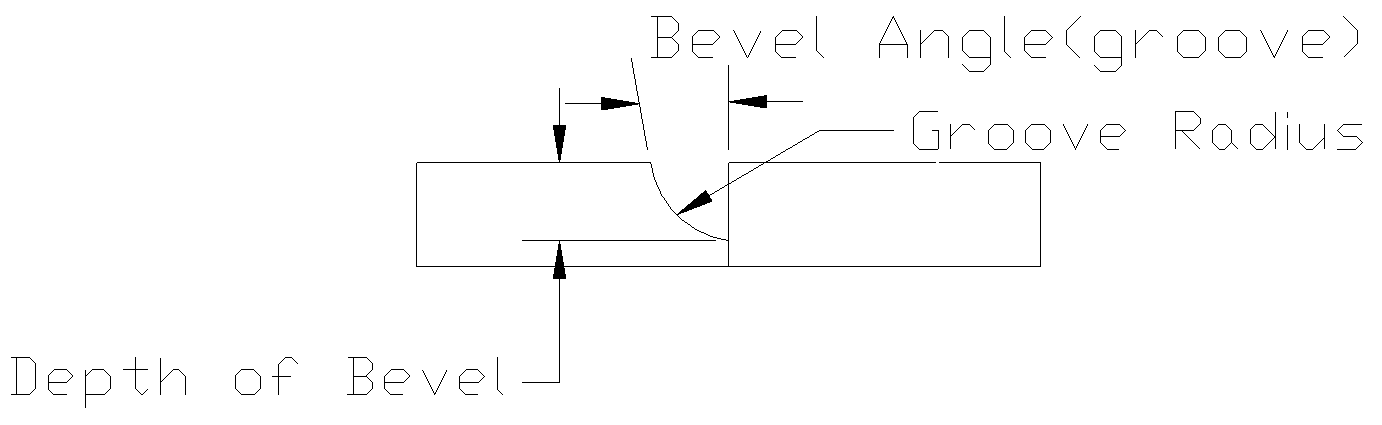

Depth of Bevel- the distance from the surface of the base metal to the root edge or beginning of the root face.

Groove Angle- an included angle of the groove between work pieces. If both members are prepared this angle is from groove face to groove face. This dimension is shown in degrees above or below the welding symbol depending on if it is arrow side or other side designation.

Groove Radius-This pertains specifically to J or U groove welds as these have a radius most commonly specific by machining.

Root Opening- a gap between two joining members.

Joint Root Examples. Some may be shown with hatching.

Groove Face, Root Edge, Root Face examples. Some are shown with or without hatching to better depict a visual.

Shown below are examples of bevel angle, groove angle, depth of bevel, groove radius, and root opening.