10 Edge Weld Symbols

Edge weld symbols are most commonly associated with sheet metal or “gauge” material. This gauge is a system used in order to call out sheet metal similar to that of electricians and wire. This chart can range from the largest gauge of carbon steel at #7 which is a decimal of .1793” all the way to the smallest which is #28 at a decimal of .0149.” This system is much simpler than using a fraction for how small these numbers are. It is also important to know that there are specific charts for carbon steel, aluminum, stainless steel, brass, copper, and galvanized steel.

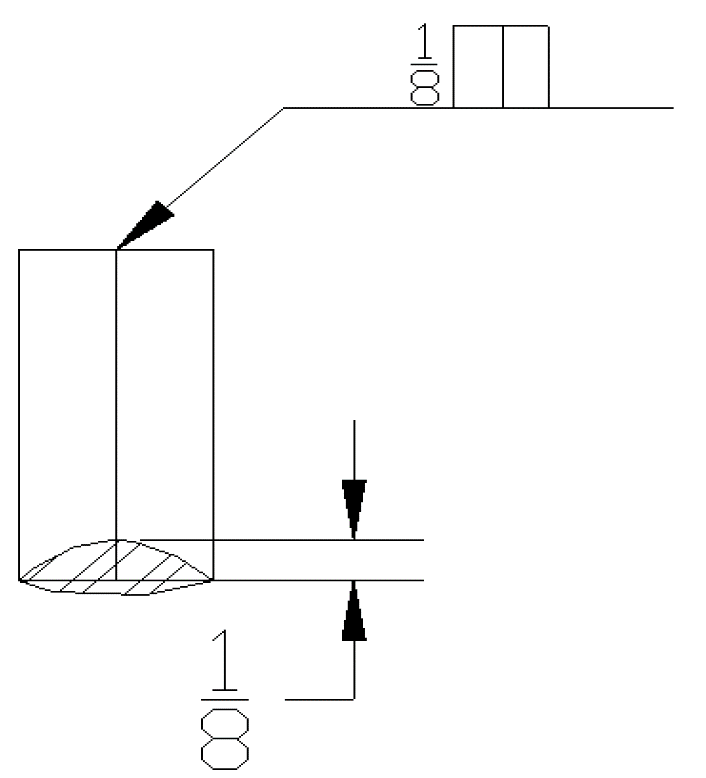

The edge weld may include a weld size which will be shown to the left of the weld symbol. The weld size is a measurement of depth of fusion, not necessarily the width of the weld. This does not mean these dimensions couldn’t be the same. If there is not a size specified it will be up to the welder’s discretion.

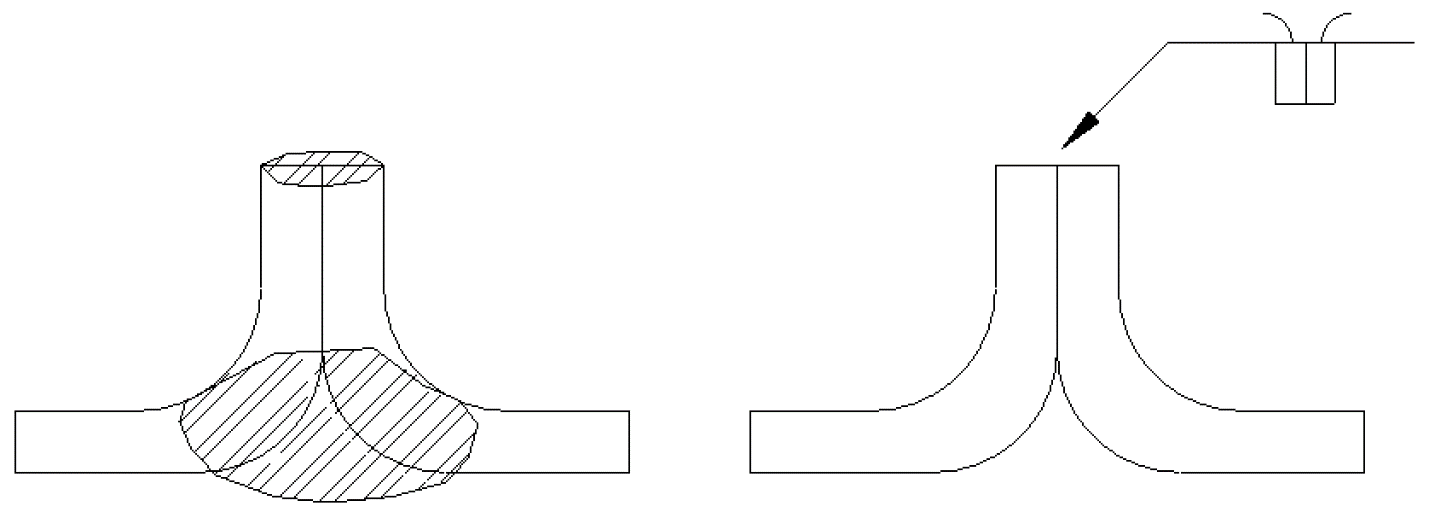

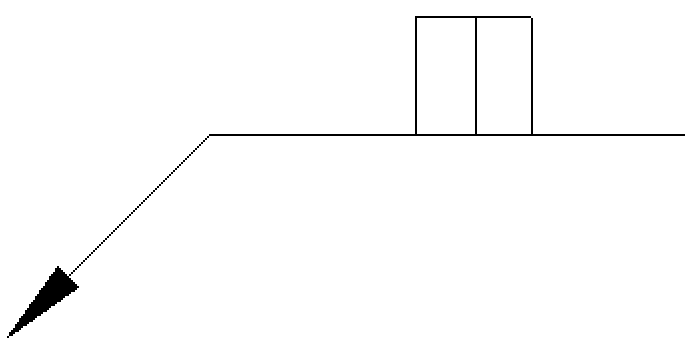

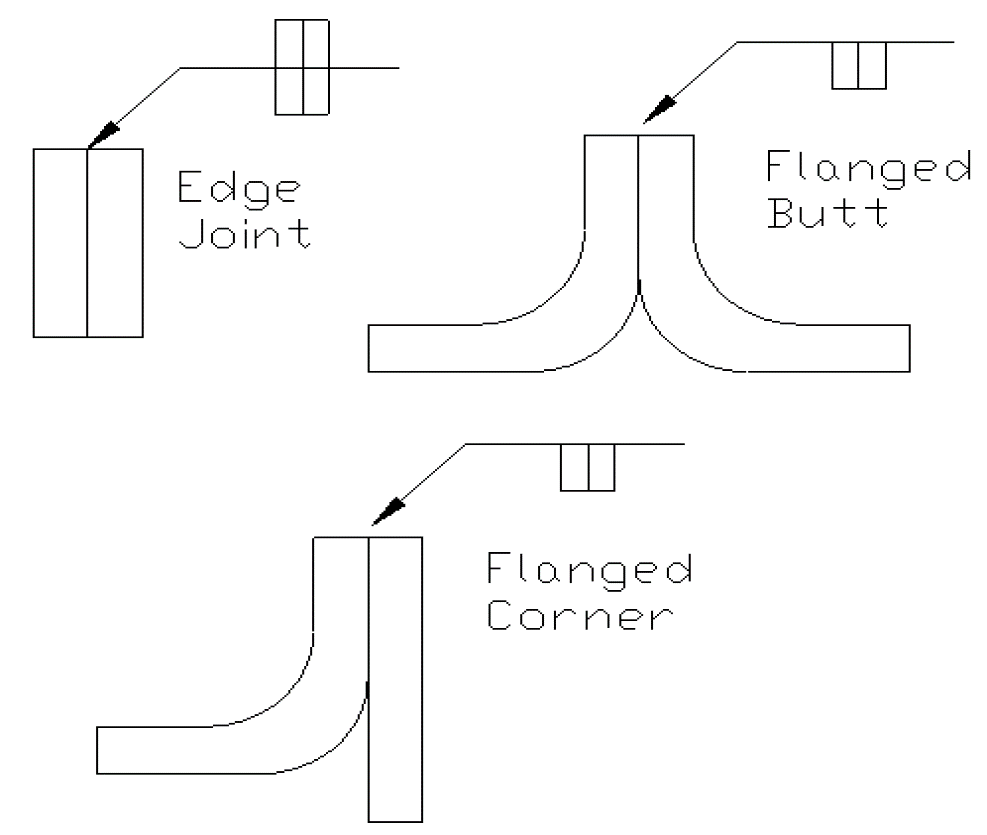

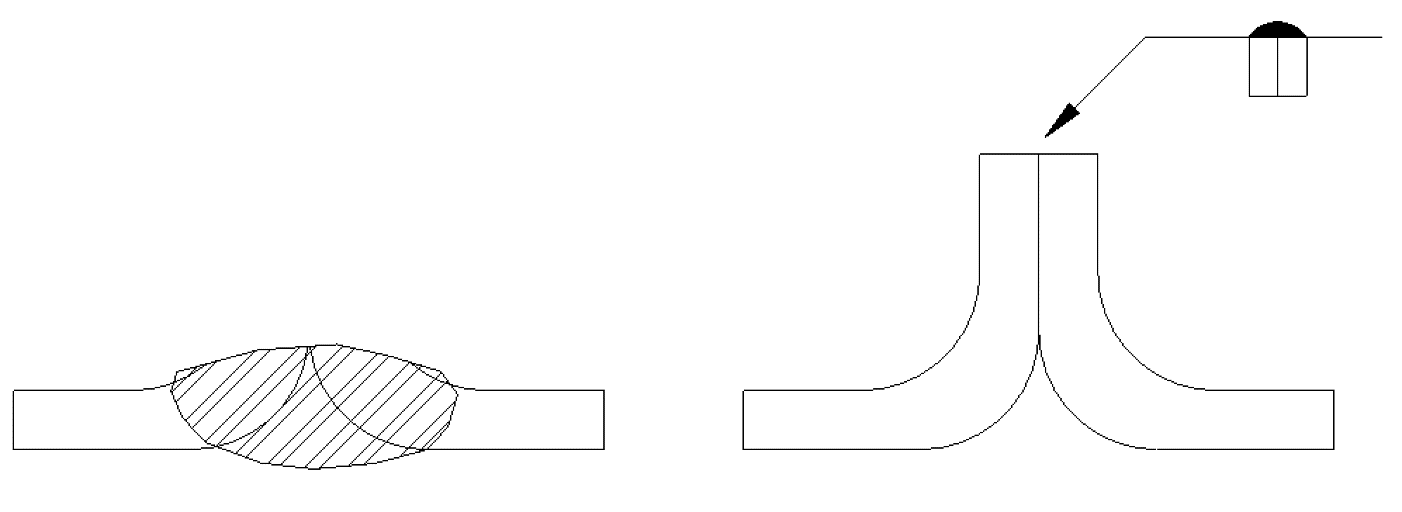

Single sided edge welds are used on edge joints, flanged butt joints, and flanged corner joints. If there is a double edge weld it will be used only with a flat edge joint. This is shown below:

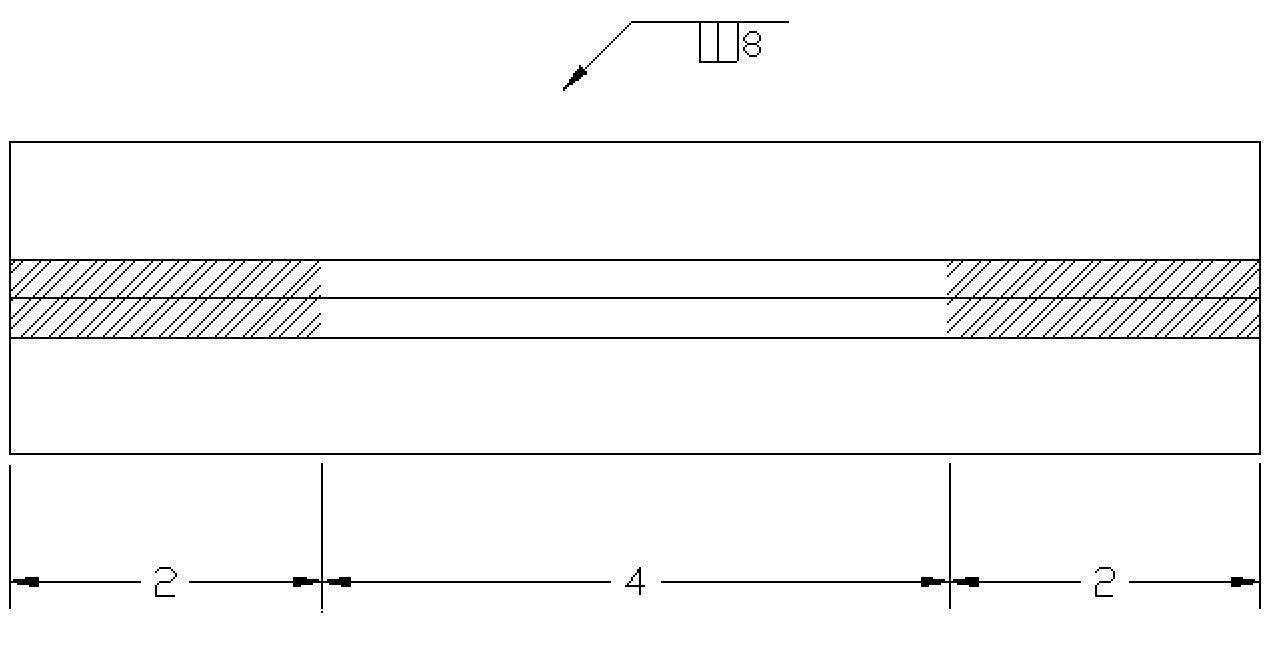

For edge welds a length can be associated with the symbol and it will be shown to the right of the weld symbol. If there is not a dimension shown to the right it will be full length of the part. There may be other indicators shown on a print of what weld length is required by using hatching or notes. Below shows an edge symbol with an 8” length as well as a detail view of a part to show specifically where two 2” welds will be located.

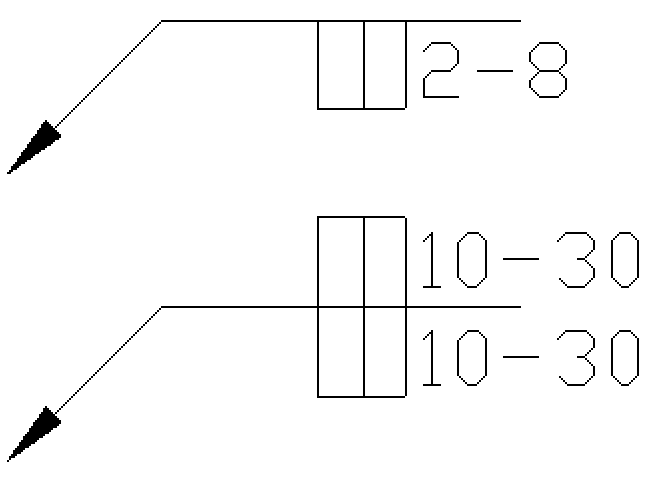

In chapter 3 Fillet Welds there was a section on length and pitch. An edge weld can also be welded in this same manner. This will be shown to the right with length followed by a hyphen and then the pitch. This can also include a chain intermittent edge weld for an edge joint. This will be more common with thicker material when it is a lengthy weld.

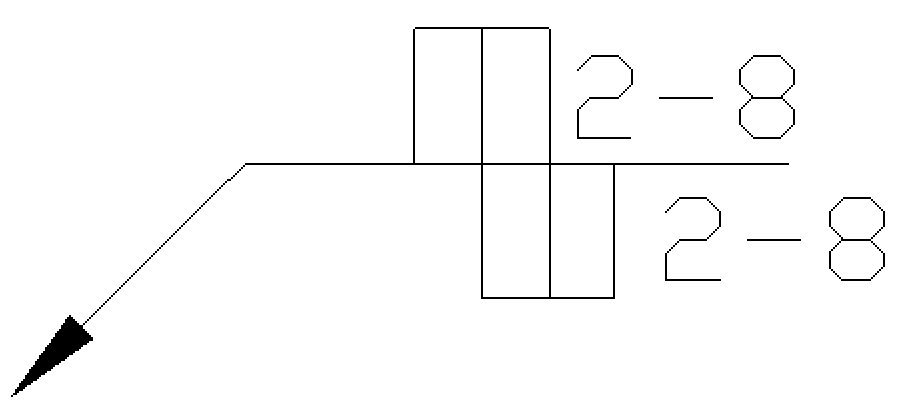

There may be a staggered intermittent edge weld as well. This is shown the same as a chain intermittent edge weld but the symbols will be offset.

When the location for these welds are not obvious it will be called out on the blueprint. This may come from a note or detail drawing or even by using extension lines.

Some edge welds will be including more than 2 members. In this case there will be only one arrow that points at the joint but encompasses all of the members. This will be more common with sheet metal.

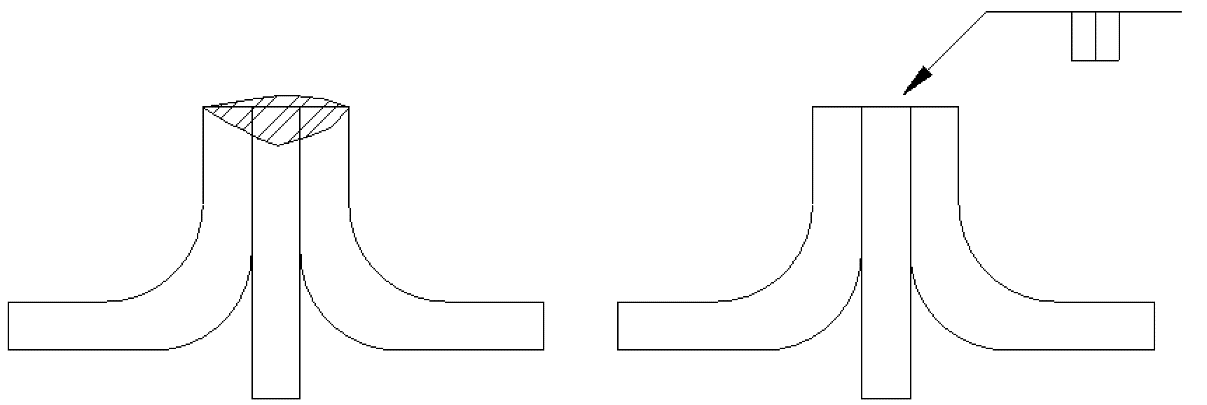

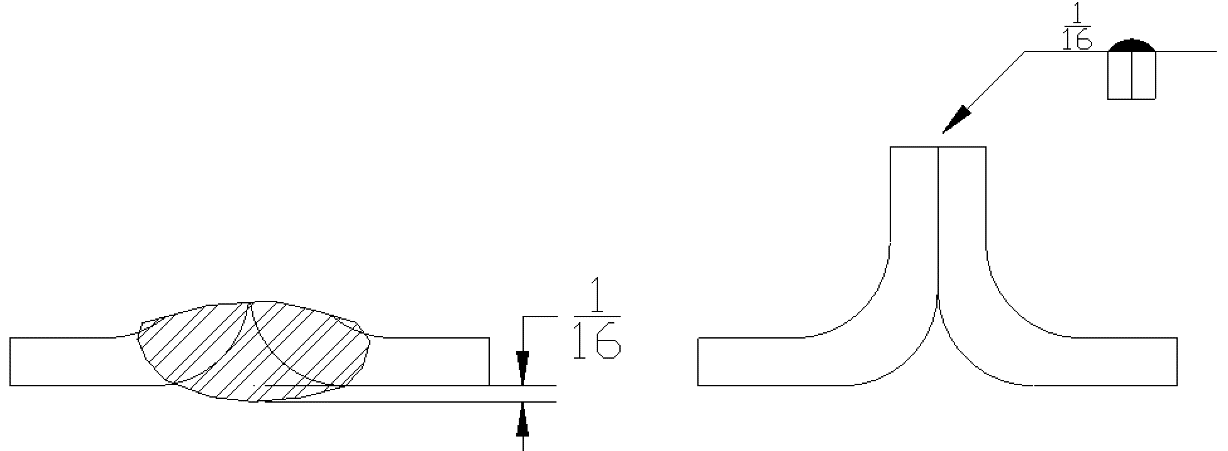

With an edge joint on a flanged butt joint or corner joint there could be the possibility of melt through. This is talked more in detail in Supplementary Symbols. When this symbol shows it is an indicator that the weld is by design supposed to burn through the back side of the material. This is quite common with sheet metal when the worry of burning a hole or something of the sort is a concern.

Melt through may be left as simple as the symbol or it may include a size. This is shown to the left of the symbol and indicates how much penetration past the weld joint is required. This is referred to as melt-through.

Another type of weld that is commonly seen with an edge weld is a flare bevel or flare v groove. This is because the opposite side of the edge is exactly that type of configuration. This may be called for on materials that adequate melt through cannot be achieved or an engineer’s request.