10.3 Hazard Controls

Hazard controls are practices or systems used to minimize risk. Effective controls minimize the potential for problems related to exposing individuals or the environment to a hazard. In the chemistry lab we think of most hazards as chemical hazards, though it is also common to encounter electric, slip/trip/fall, and fire hazards in this setting.

In work environments that are not primarily used as chemistry laboratories, the concept of controls is still useful. For instance, infection controls are a standard way of managing the risk to workers in hospitals, where individuals who carry infectious disease occupy a building with one another and a cadre of workers who move through the facility.

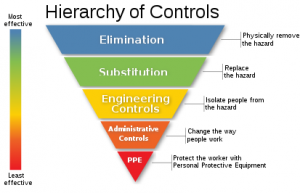

The national government agency NIOSH (National Institute of Occupational Safety and Health) developed a hierarchy of controls, such that the items at the top of the hierarchy are most effective at reducing risk.

Take a moment to reconsider the earlier example of risk to health and environment from the hazardous material, gasoline. Gasoline is highly flammable and is toxic by inhalation (breathing vapors) and through contact (skin contact or through contact with mucous membranes). How do we control the risk to health from exposure to this substance?

The most effective way to reduce your risk is by removing gasoline from your life (Elimination). But since many of us consider it an important substance to use, we protect ourselves by pumping it into our cars using special pumps that minimize our exposure to it. The pumps and our cars are engineered to isolate people from the hazard (an Engineering control). For those who work with gasoline all day, instructions to keep the hose pointed away from themselves are given (administrative control). These workers may also wear gloves or other protective clothing (PPE) to help them avoid exposure.

Note that in this example it is possible to identify a specific example of each type of control, with the exception of Substitution. Substitution would occur if gasoline were replaced with a different fuel that did not have the problematic hazards.

In the chemistry lab similar thinking is employed to minimize exposure to hazards, decreasing the risk of harm to students or workers who occupy and work in the lab.

Apply your understanding

For each example describing an adjustment to a lab procedure, identify which of the types of controls best describes the nature of the risk reduction:

| Example | Type of control |

| Fume hoods are used to boil a substance that releases vapors that are hazardous by inhalation. | |

| Students are told to tie back their hair when working with a Bunsen burner. | |

| Concentrated hydrochloric acid (12M) is replaced with a more dilute solution (3M) to acidify a sample. | |

| One part of a lab procedure is removed since the learning objectives for the day can be met without it. | |

| Students are told to wear their safety glasses. |

The examples here demonstrate that controls on the bottom end of the hierarchy are not unimportant. However, for any hazard it is preferable to work at the top of the hierarchy to manage any particular hazard, if there is an option to do so. In the absence of satisfactory risk reduction from controls at the top of the hierarchy, we do often resort to things like PPE. Use of protective equipment is essential when the risks are real and the potential harm (damage to eyes and possible loss of vision in the case of eye protection) is great.

Engineering controls in a chemical laboratory often include air handling systems, the use of inert materials for benchtops and floors, placement of disposal areas and sinks near workers, and more.

Administrative controls in the chemistry lab include expectations for behavior that

Administrative controls in the chemistry lab include expectations for behavior that

prohibits climbing, running, or throwing objects in the lab.

PPE used in the chemical laboratory always includes eye protection. Gloves, laboratory coats, face shields, hearing protection and insulated gloves are also frequently used.